|

|

|

|

|

PICTURES AND INFORMATION RECENTLY ADDED TO THIS SITE

These following informaiton was recetly added to the haddockjaguar.com website. While it was placed in other sections, it is repeated here to allow easy viewing of recent material.

|

|

|

|

|

|

N-11Y

|

|

|

|

|

|

|

|

|

|

Tail light

Left rear view of a restored 3.8-liter roadster.

|

|

|

|

|

|

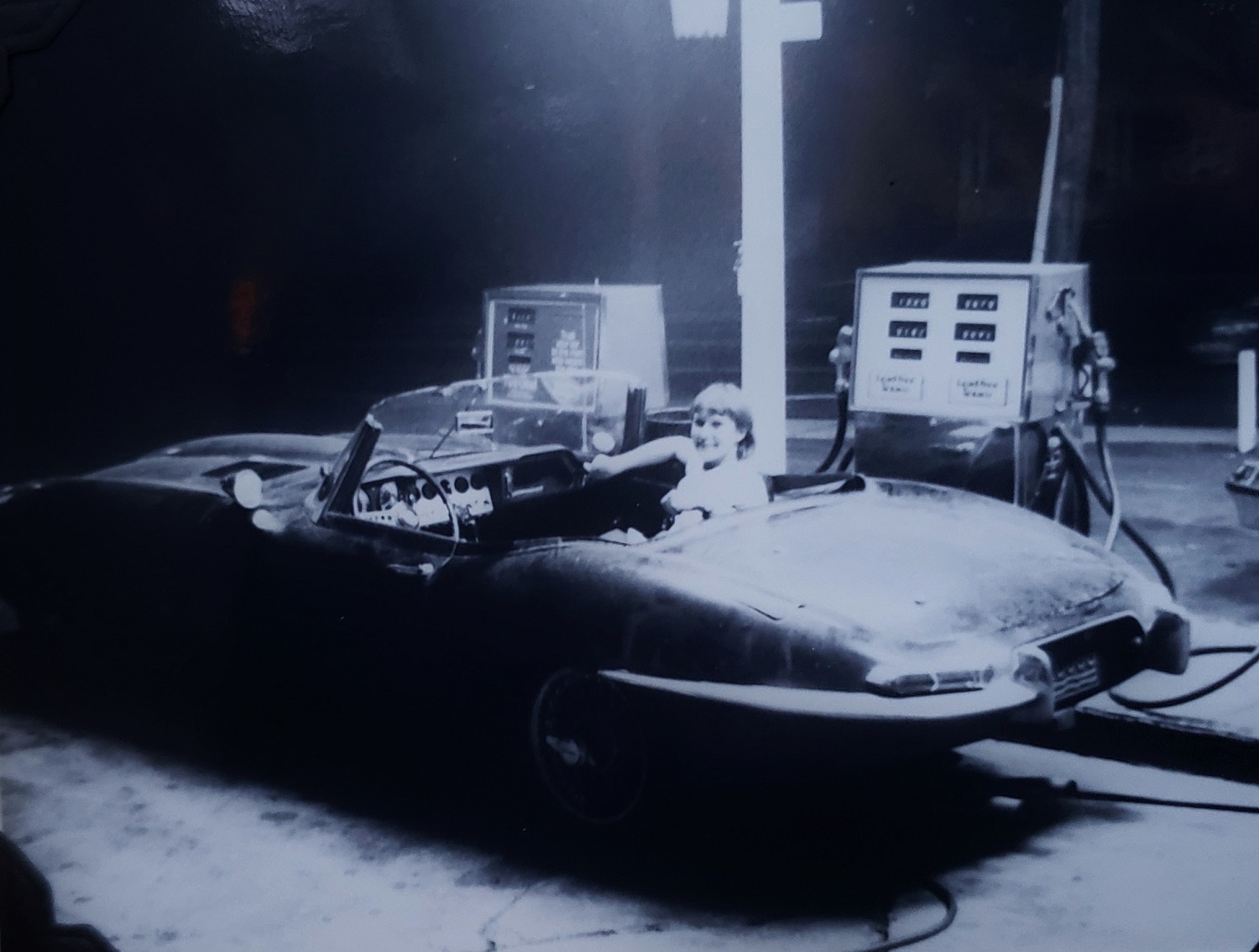

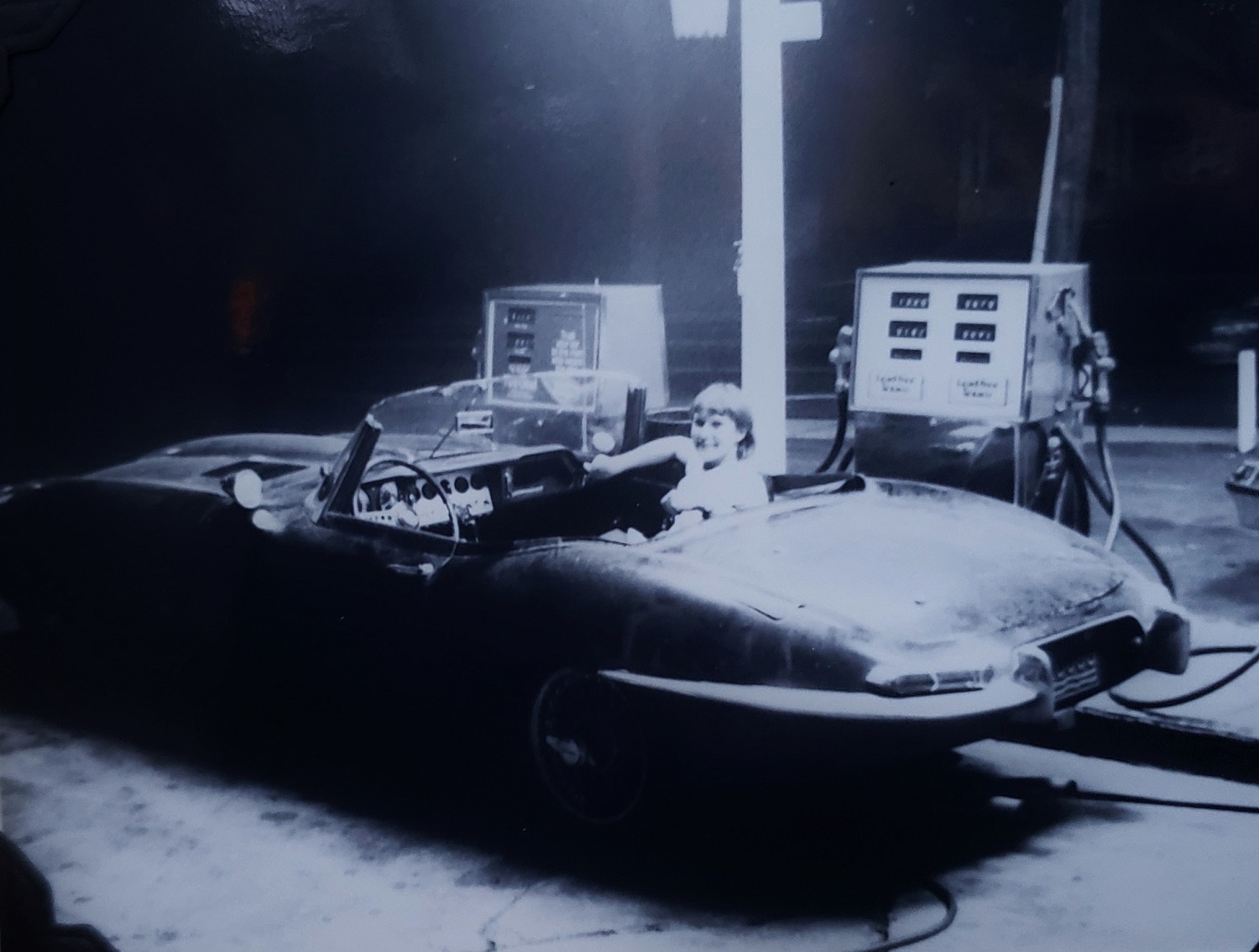

Night fuel stop

E-type on a road trip in the 1970s.

Sitting in a gas station off a country two-lane.

|

|

|

|

|

|

|

|

|

|

E-type roadster parked on a lawn

|

|

|

|

|

|

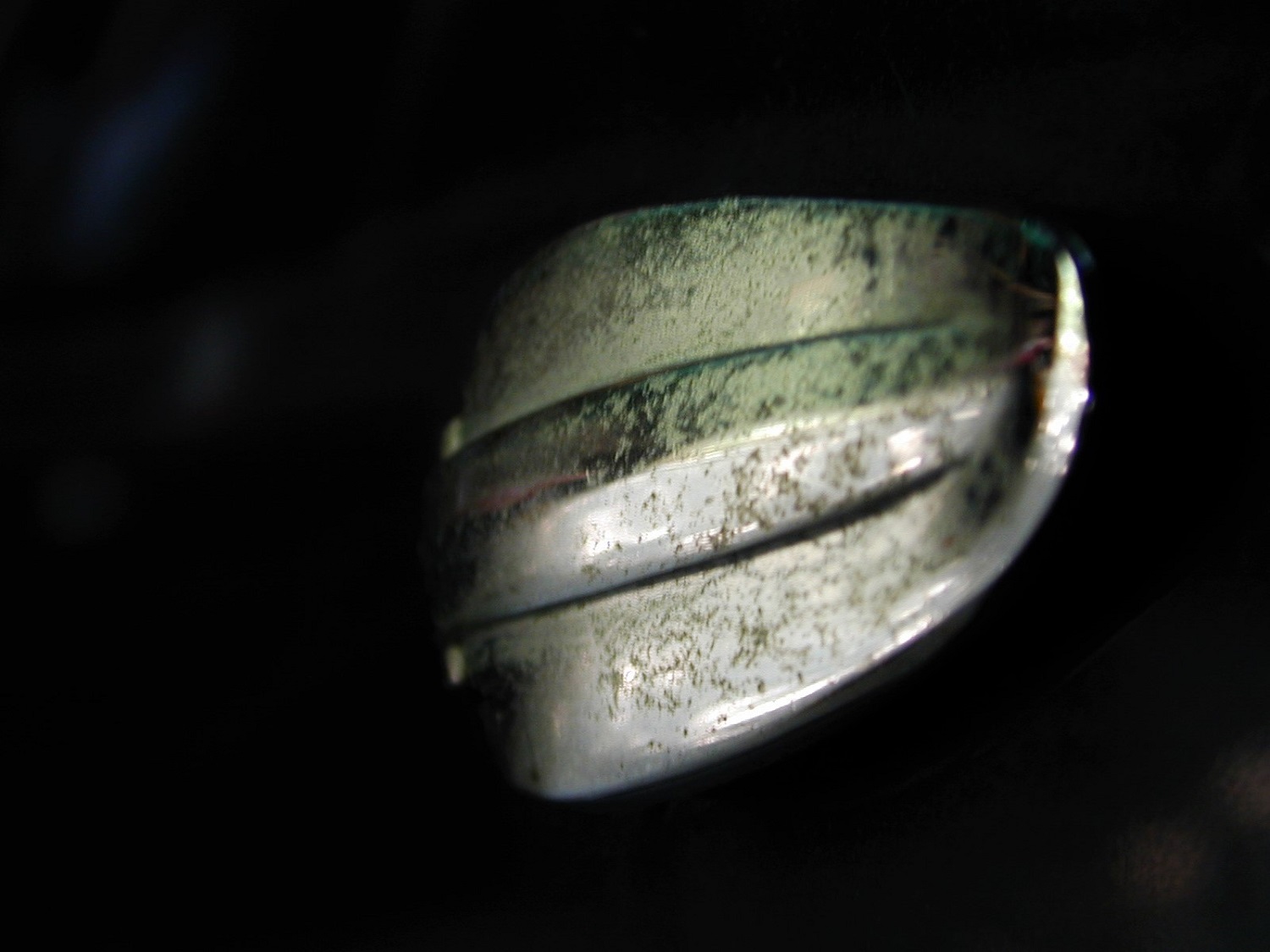

Talbot racing mirror marking

The raised stamped region of a Talbot racing mirror shows the name and origin of the maker, Talbot & Co.

This image was taken looking straight down on the chromed surface of the flat circular stamped area, and the dark circular region is a reflection of the dark camera, not the color of the mirror surface, which is polished chrome.

|

|

|

|

|

|

|

|

|

|

Trunk-lid labeling on a V-12 roadster

The markings seen here on this V-12 car indicate the engine configuration, but not the 5.3-liter displacement.

The prior model, the 4.2-liter six-cylinder E-type stated the displacement, and also had the "E TYPE" label. The earliest 3.8-liter cars had only the "JAGUAR" label.

While most of the lettering is basically flat, the "V12" label is sculpted in a fully three-dimensional way. The edges of the "V" and the "12" are all angled at roughly 45-degrees to give a different reflection pattern than the rest of the letters.

|

|

|

|

|

|

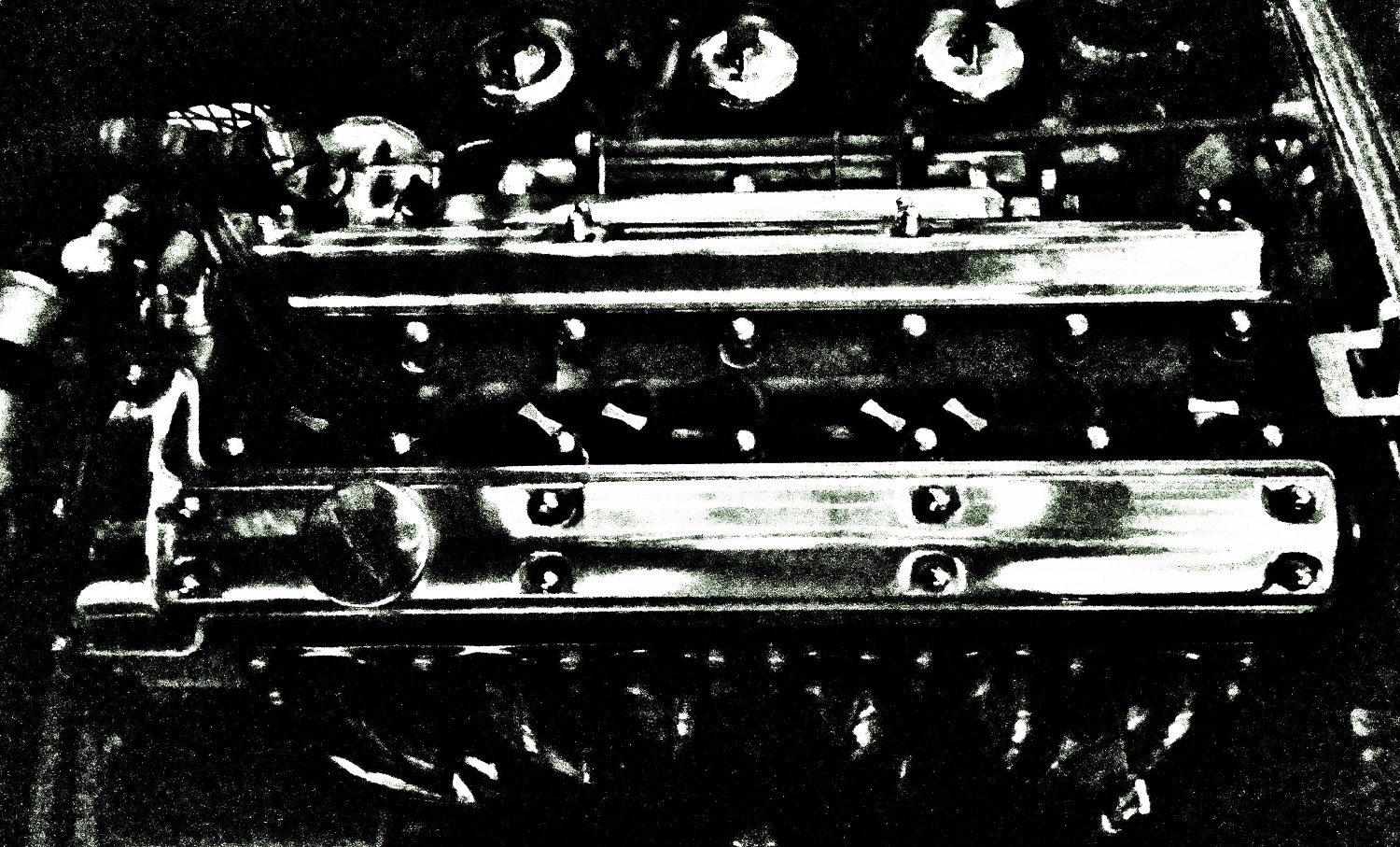

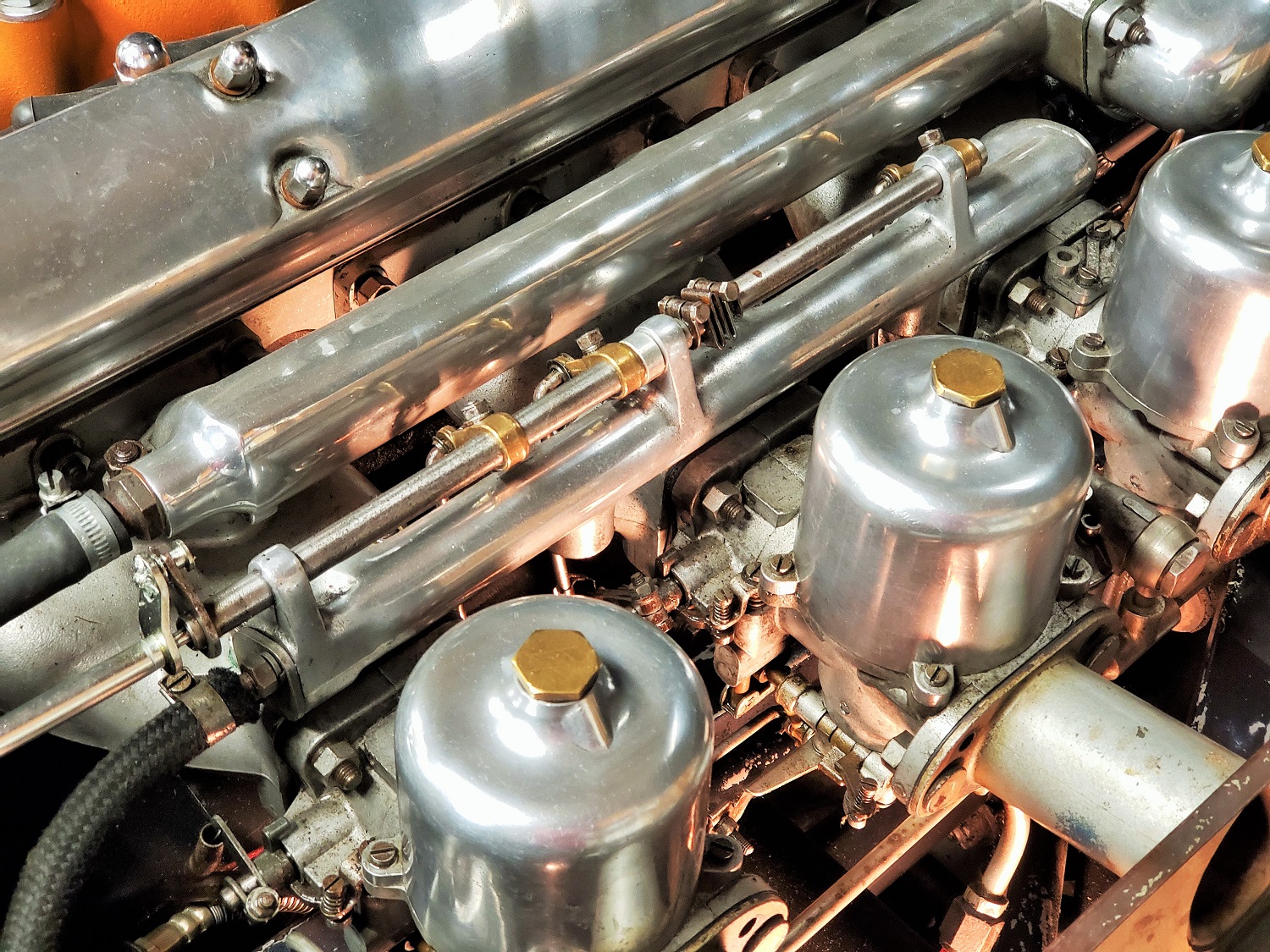

Triple SU HD8 carburetor set, as fitted to early E-types

While all of the S-type XK engines fitted to the Series 1 E-type cars (as well as MkX sedans) had triple SU HD8 carburetors, the design of the carburetors and manifolds evolved over time.

This set shows a relatively early configuration.

|

|

|

|

|

|

|

|

|

|

Horn button

Even though this E-type horn button is discolored and has some cracks, it, like all other parts of the E-type, still presents elegantly.

|

|

|

|

|

|

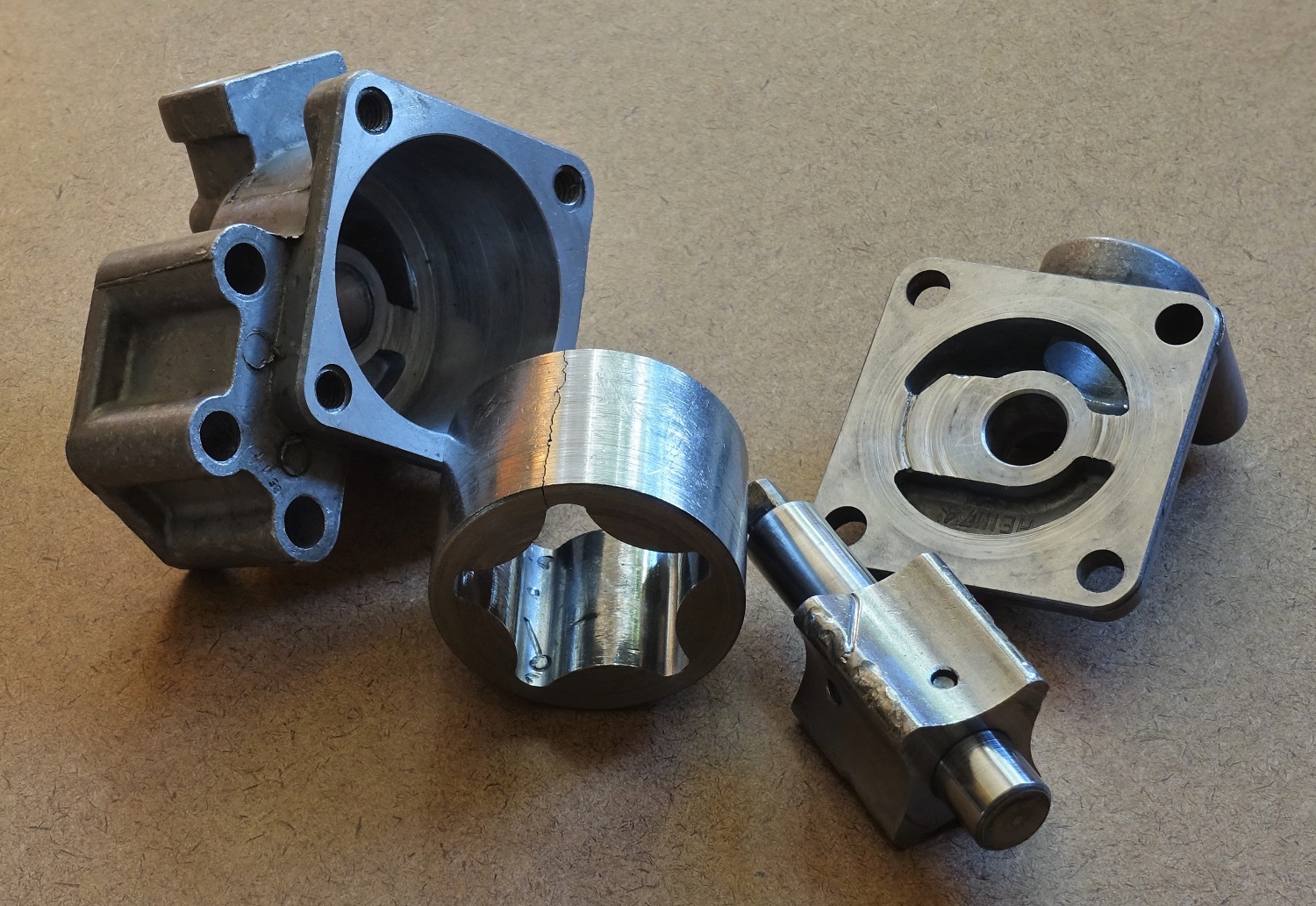

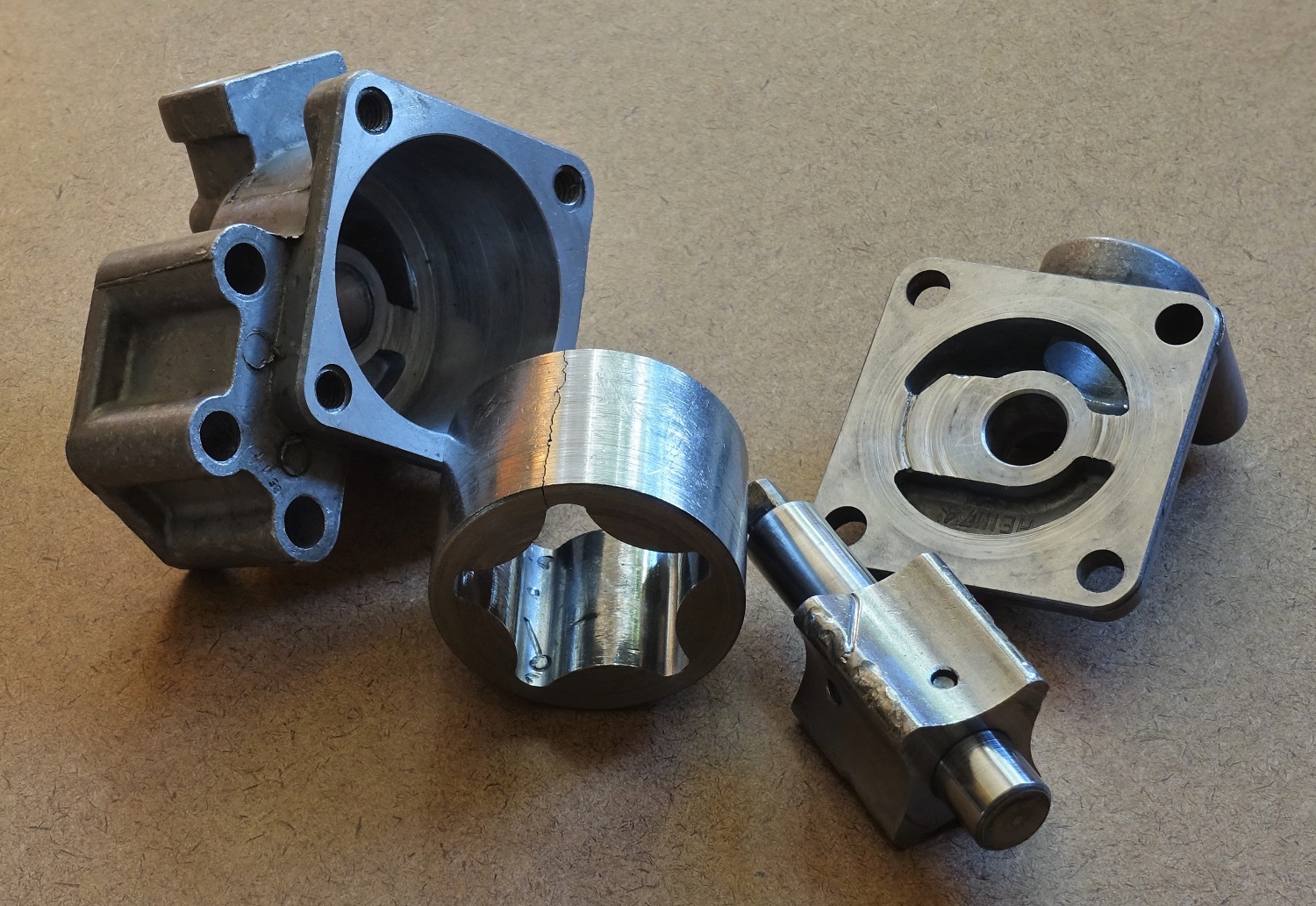

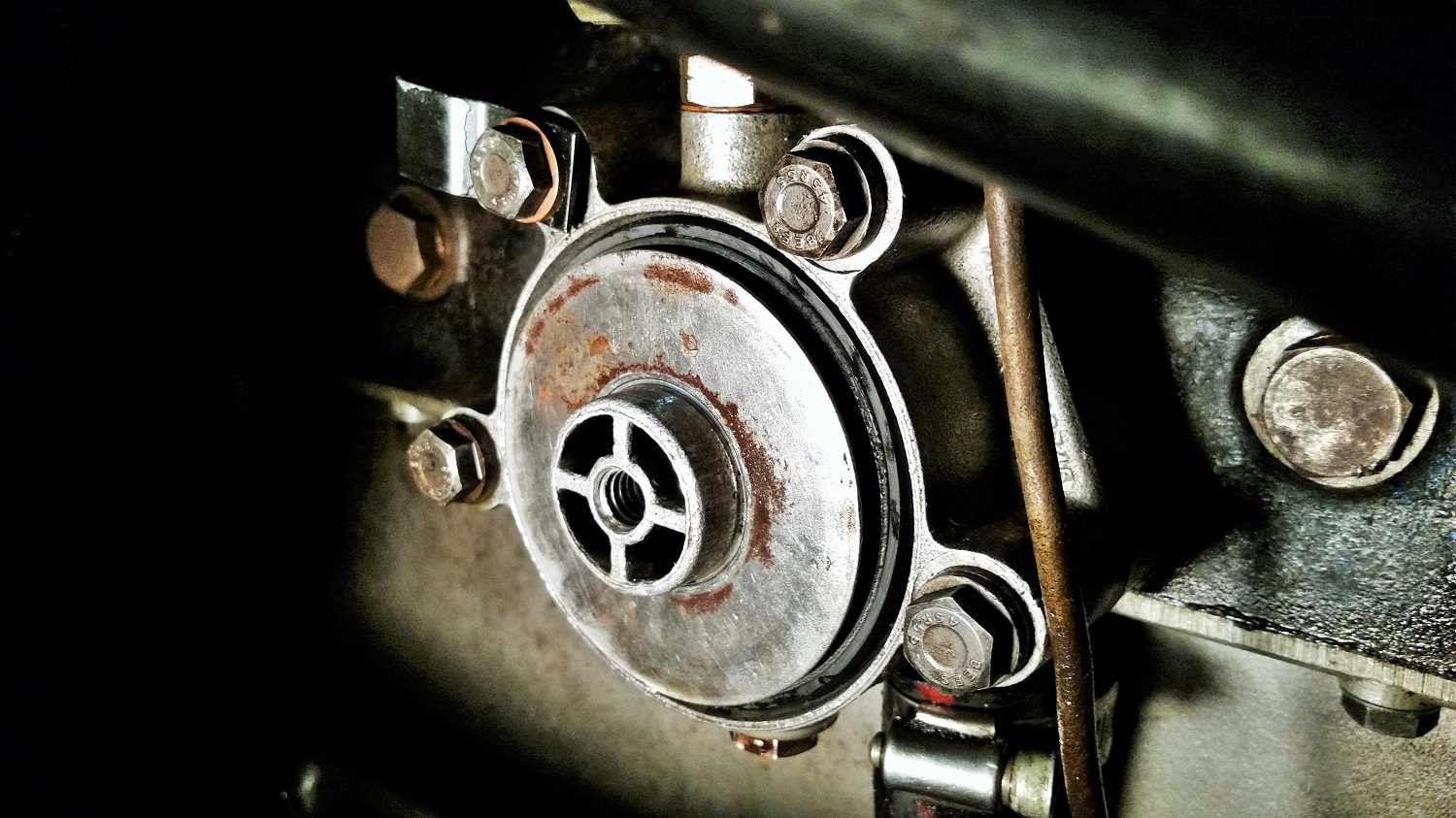

Cotter-pin oil-pump damage

Here cotter pins broke off from their positions at the ends of the castellated con-rod bolts and were sucked into the oil pump.

Their images can be seen on the inner surface of the outer rotor in the lower center of the picture, as well as on the outer surface of the inner rotor in the lower right quadrant of the picture.

In addition, a crack in the outer rotor can be seen in the center of the picture, likely caused by the cotter pins being forced through the pump.

Gouges can be seen in the aluminum cover; similar gouges are present in the aluminum housing.

This is a relatively common occurrance, at least on engines that were rebuilt in-period. Many times the first thing to be seen upon sump removal was broken-off cotter pins.

|

|

|

|

|

|

|

|

|

|

E-type Jaguar

|

|

|

|

|

|

SU HD8 carburetor

This carburetor, removed for service, shows the early style brass-top dampener.

|

|

|

|

|

|

|

|

|

|

Steering wheel

This view of an E-type steering wheel shows its laminated-wood construction.

|

|

|

|

|

|

SU HD8 carburetors

|

|

|

|

|

|

|

|

|

|

E-type in the rain

|

|

|

|

|

|

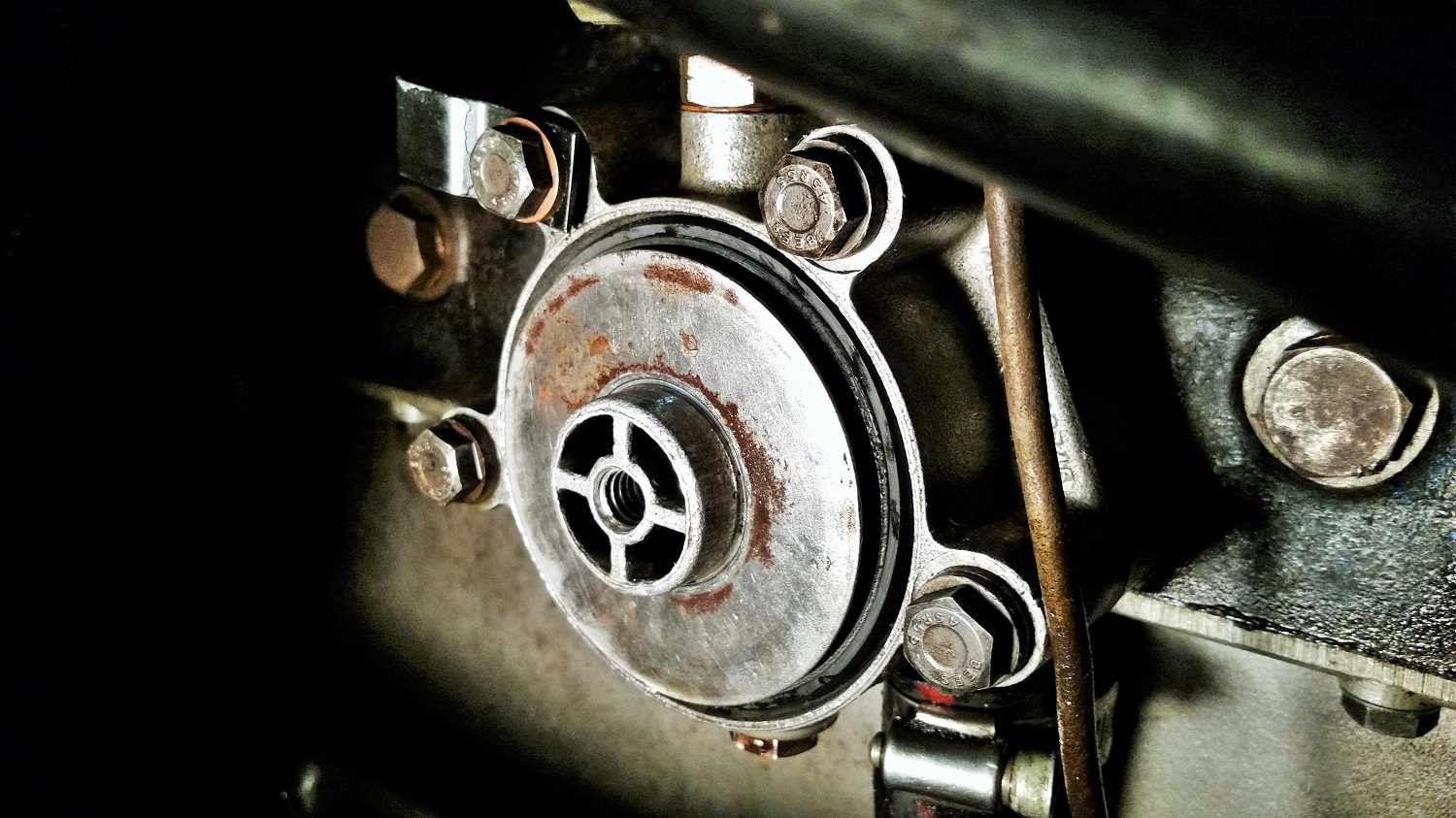

Oil filter head with filter removed

This filter head is seen mounted on the lower central right-hand side of a 3.8-liter E-type engine block. Various sorts of filter heads were used on the different versions of XK engine.

|

|

|

|

|

|

|

|

|

|

Muffler assembly

This muffler assembly spent many decades under a Series 1 E-type Jaguar. It was originally acquired as a replacement by aftermarket supplier J.C. Whitney.

|

|

|

|

|

|

Night driving in a 4.2-liter E-type coupe

|

|

.jpg)

|

|

|

|

|

|

|

|

Early-style fuel tank sump

The early sumps were made up of individual pieces that screwed together, while later designs were of a fabricated single-peice design.

Here the brass bottom piece and be clearly seen. It can screw off from the main body.

|

|

|

|

|

|

MG TD

Another popular British sports car from the period just preceeding the introduction of the E-type.

|

|

|

|

|

|

|

|

|

|

Porsche 356

The 356 series was in production during the period leading up to the E-type's introduction in 1961, and on into 1965 when the 911 came out.

|

|

|

|

|

|

Early Series 1 glass windshield washer bottle

After de Chirico.

|

|

|

|

|

|

|

|

|

|

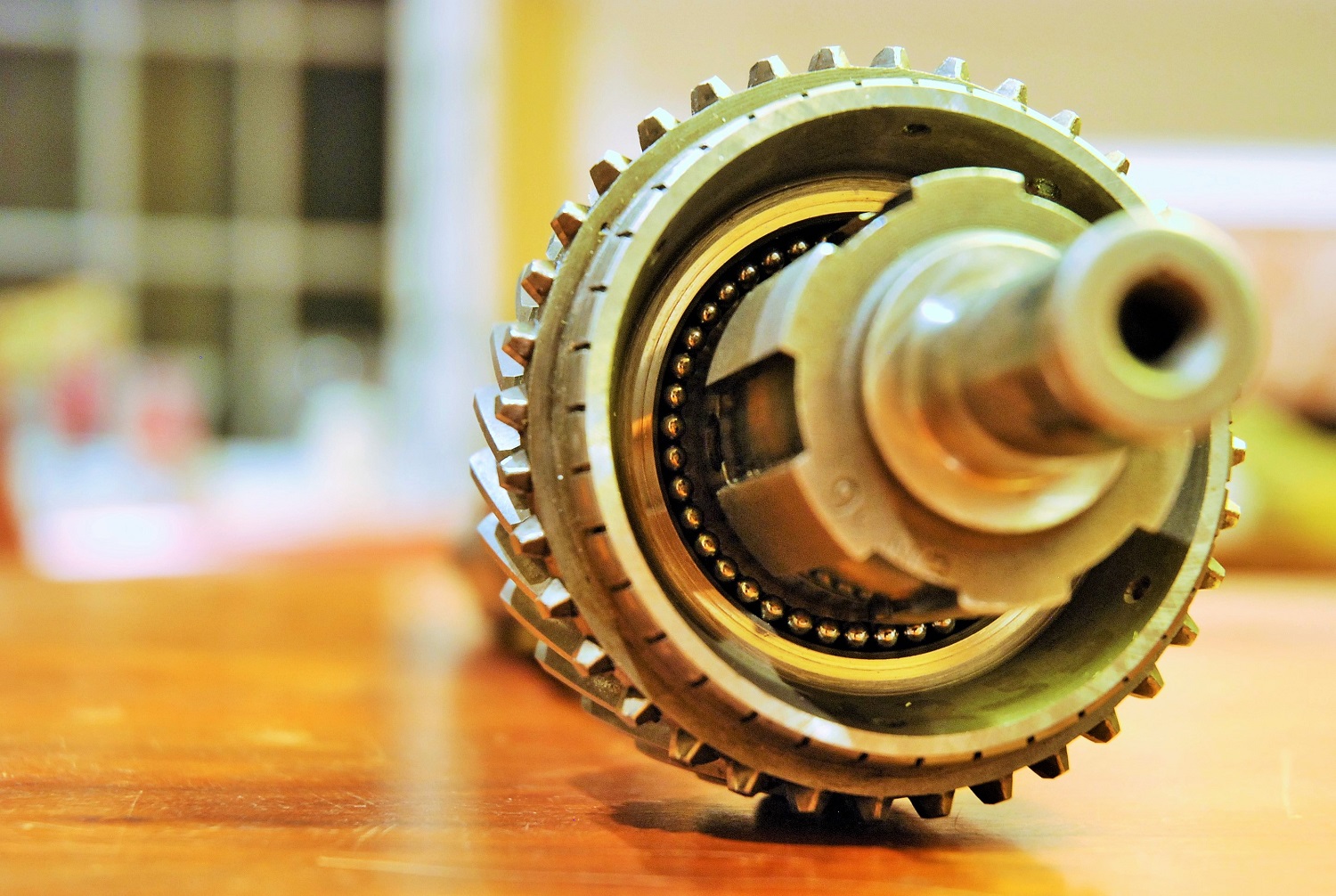

Third gear needle bearings on a Moss gearbox

The ends of the needle bearings between third gear and the output shaft are seen here.

The part of the output shaft in the foreground is where the shaft inserts into the constant pinion shaft.

There will be needle bearings at this juncture as well, but they are caged, as opposed to the third-gear needle bearings seen here that are free.

|

|

|

|

|

|

Dunlop wire wheels

Early-style chromed 72-spoke double-laced Dunlop wire wheels during transport.

These are the type of wheels used on Series 1 E-types. In some cases, they were painted instead of chromed.

|

|

|

|

|

|

|

|

|

|

Champion spark plugs in an XK engine

Champion spark plugs were the type oringally fitted to Jaguar E-types.

The spark-plug location in the center of the head well made them very easy to access, in contrast to some cars with different engine configurations.

|

|

|

|

|

|

Dusk

|

|

|

|

|

|

|

|

|

|

Mounts for front antiroll bar

These mounts are comprised of sheet-steel brackets sitting on cast aluminum spacers.

Black rubber bushings are located around the antiroll bar where it passes through these brackets.

|

|

|

|

|

|

XK-120

Sitting on a cement slab in a storage facility.

|

|

|

|

|

|

|

|

|

|

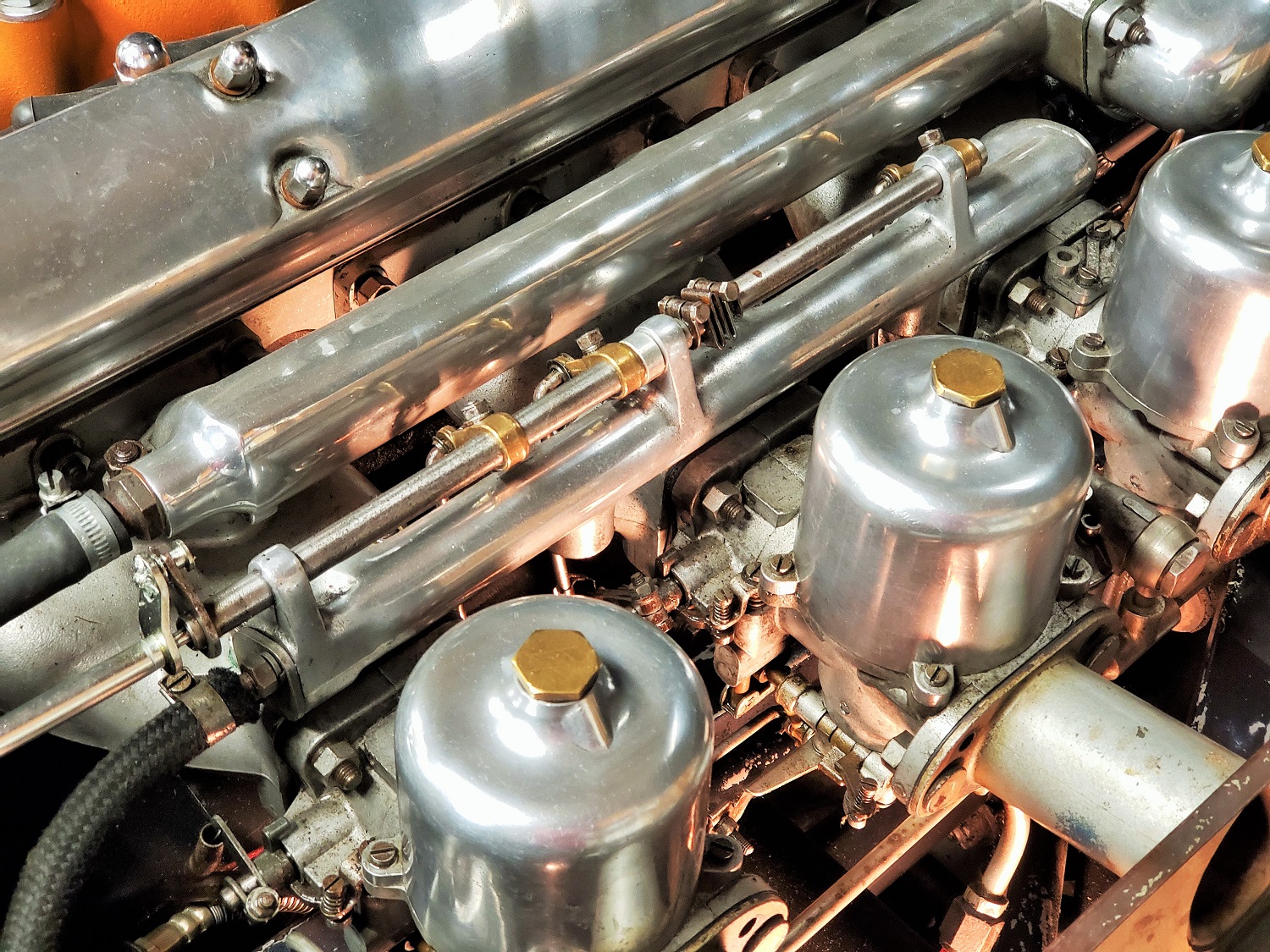

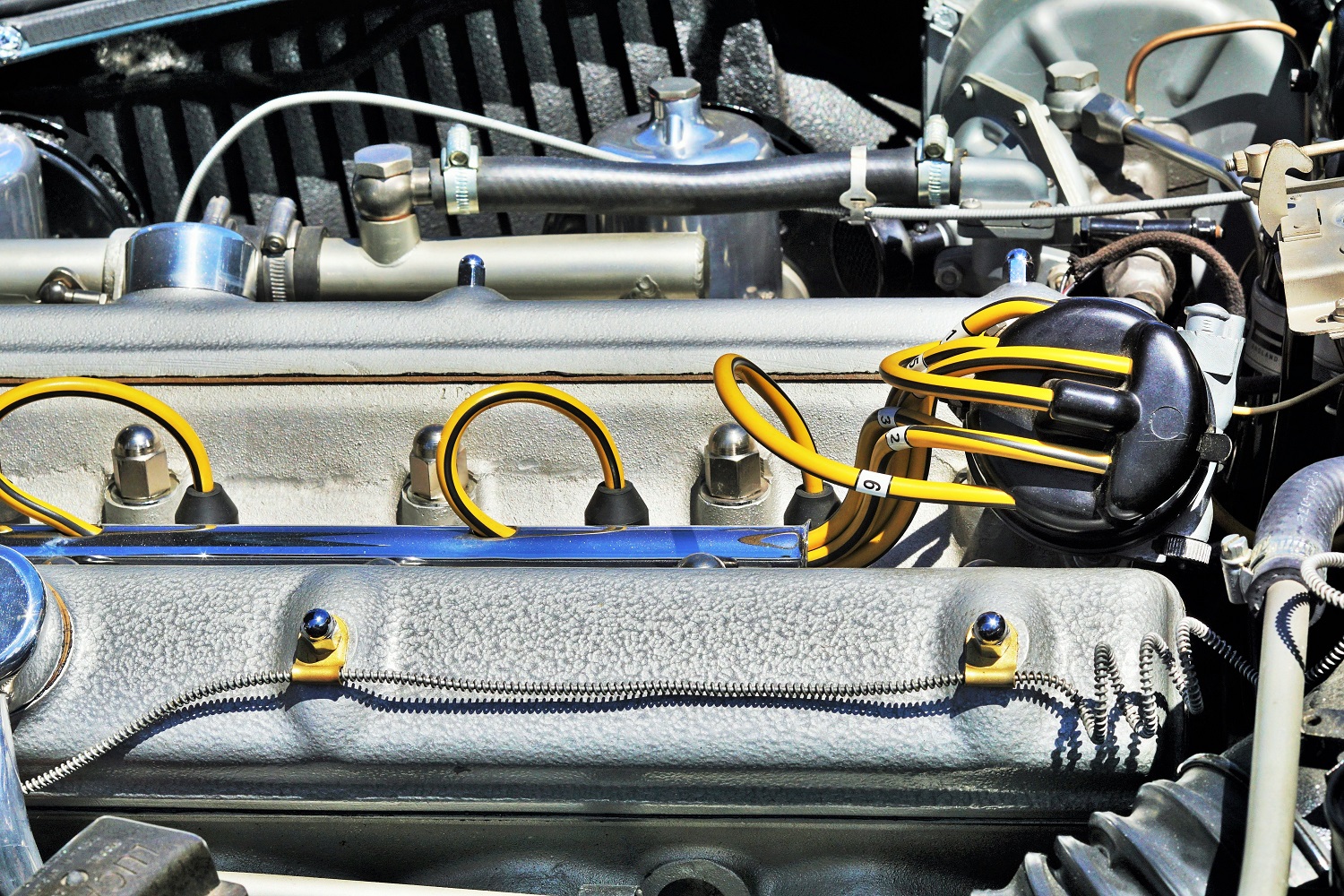

Aston Martin engine

This restored Aston Martin engine has some similarities to the XK engine, as used in the E-type, including SU HD8 carburetors and chrome domed cylinder-head nuts.

The distributor mounting at the rear of the head is markedly different, though, as well as the single studs holding down the camshaft covers.

|

|

|

|

|

|

Plastigaugeing an XK engine crankshaft

Checking clearances during a rebuild.

|

|

|

|

|

|

|

|

|

|

Shelley jack

|

|

|

|

|

|

E-type wire wheel

Moving out of storage in the winter.

|

|

|

|

|

|

|

|

|

|

Distributor and oil pump drive system

The gear in the upper left of the picture is driven off the helical gear on the front of the crankshaft, seen to its right.

The cylindrical coupler just below the gear drives the oil pump, the top of which is seen in the bottom left of the picture. The distributor is driven off the upper part of the shaft, not seen in the picture.

The front crankshaft main-bearing cap is seen in the lower right of the picture.

|

|

|

|

|

|

A home shop in the evening

E-type in an informal setting.

|

|

|

|

|

|

|

|

|

|

Cooling fan winding down

When the ignition is turned off, after a drive.

|

|

|

|

|

|

Heater blower fan

Forced air for ventillation and heating was driven by this cylindrical fan. It was powered by a motor, mounted below, and not visible in this picture.

Here the fan and motor have been lowered out of their housing in the heater unit, located just above.

This particular motor had not run in over 50 years, but is seen here working well after the wiring was corrected.

|

|

|

|

|

|

|

|

|

|

Steering wheel hub

The E-type's steering wheel had an aluminum frame. On the Series 1 cars, the horn was actuated by the button in the center of the steering wheel. Pressing the button grounded the brass rod running through the center of the wheel.

Later, horn actuation was moved to a button on the end of the turn-signal stalk.

|

|

|

|

|

|

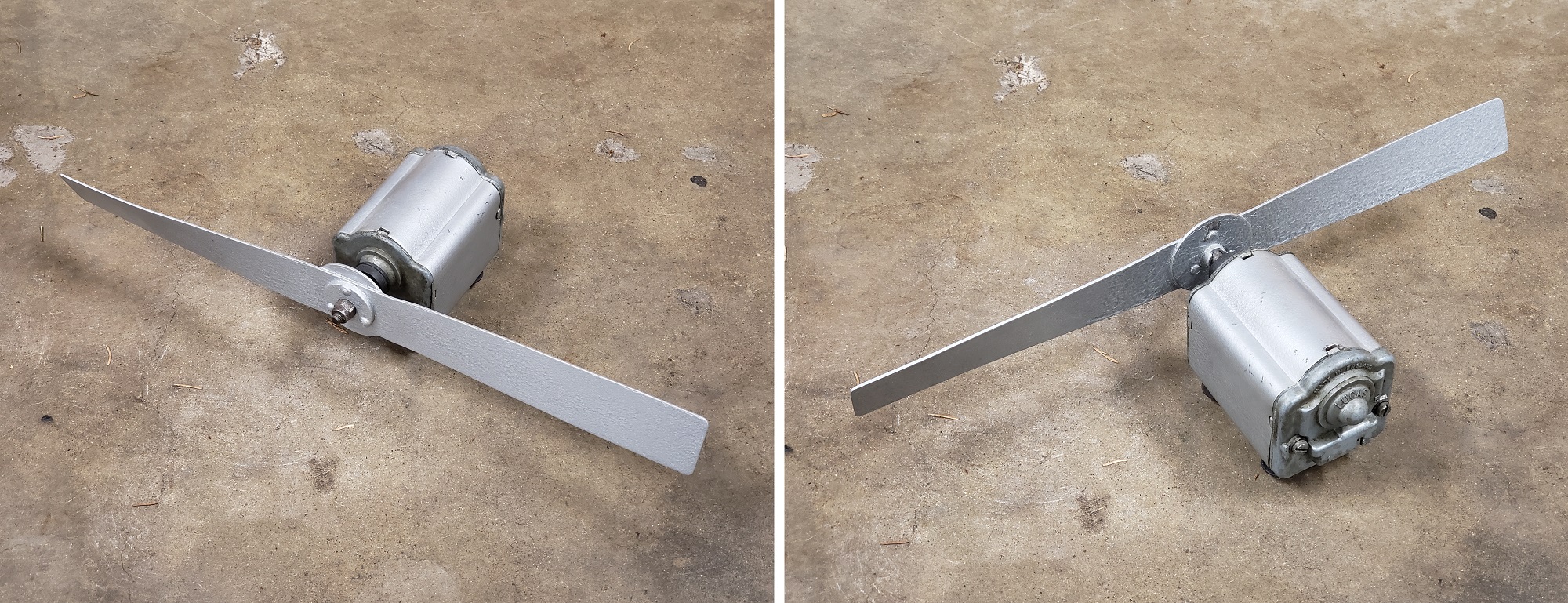

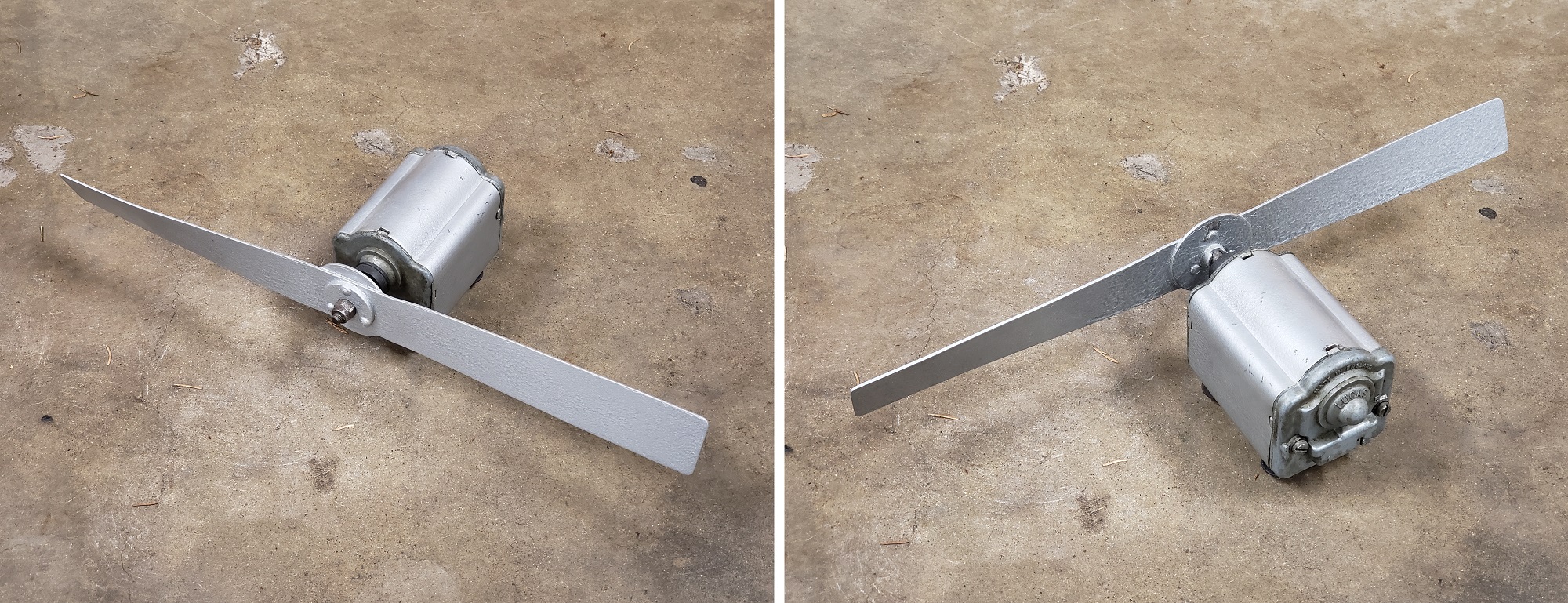

Electrically-driven engine-cooling fan

The forced airflow for engine cooling was driven by this electric fan, seen in two views here. This was one of the first, and possibly even the first, example of an electric fan used to drive air through the radiator.

The motor is similar to those used for some time previously to drive the windshield-wiper systems on various British cars, including Jaguars.

This early design is very different from the plastic cooling fans used today.

|

|

|

|

|

|

|

|

|

|

Steering wheel collets

This set of two collets were used to locate the steering wheel on its shaft.

|

|

|

|

|

|

Early morning drive

|

|

|

|

|

|

|

|

|

|

3.8-liter E-type fuel filter assembly

The glass sediment bowl collects debris by gravity. There is also a filter in the top to take out smaller particles.

When the bonnet-latch design changed from outside to inside the exact location of the filter unit changed, as discussed on page 191 of the newOriginality Book. This is the eariler configuration.

|

|

|

|

|

|

Early-style 3.8-liter S-type engine throttle linkage

The earlier 3.8-liter air-balance pipes and throttle linkages were different from the design used on later 3.8-liter cars. The linkage seen here is more similar to that of a XK-150S linkage than that of the later 3.8-liter E-type linkages.

However, there are several differences between this linkage and that of the XK-150S, including the attachment to the linkage from the accellerator pedal (not seen in this picture).

The junction between the front and rear rods was also different. Here the junction is a corrugated sheet-steel section, and on the XK-150S it was a solid piece.

|

|

|

|

|

|

|

|

|

|

Retainer for the brake pedal rod

This is the later type with two bolts; the earlier design used a single bolt, and was different in other ways.

|

|

|

|

|

|

Restored MGA

An MGA in storage. Another contemporary of the early E-type.

|

|

|

|

|

|

|

|

|

|

Unrestored 356

A Porsche 356 was a competitor to the E-type in the U.S. market. Here one sits on a trailer at the Hershey, Pennsylvania, USA, car show in somewhat rough but quite original condition.

|

|

|

|

|

|

Later-style Series 1 steering wheel

This steering wheel has been restored to the late Series 1 configuration. This is the later thin-crossection design, with the thumbgroove on the front and non-exposed aluminum ring.

Subsequent to this design, the Series 2 wheels had a brushed aluminum finished instead of the polished finish.

Series 3 cars had an alltogether different design: a dished wheel with a leather-covered rim.

|

|

|

|

|

|

|

|

|

|

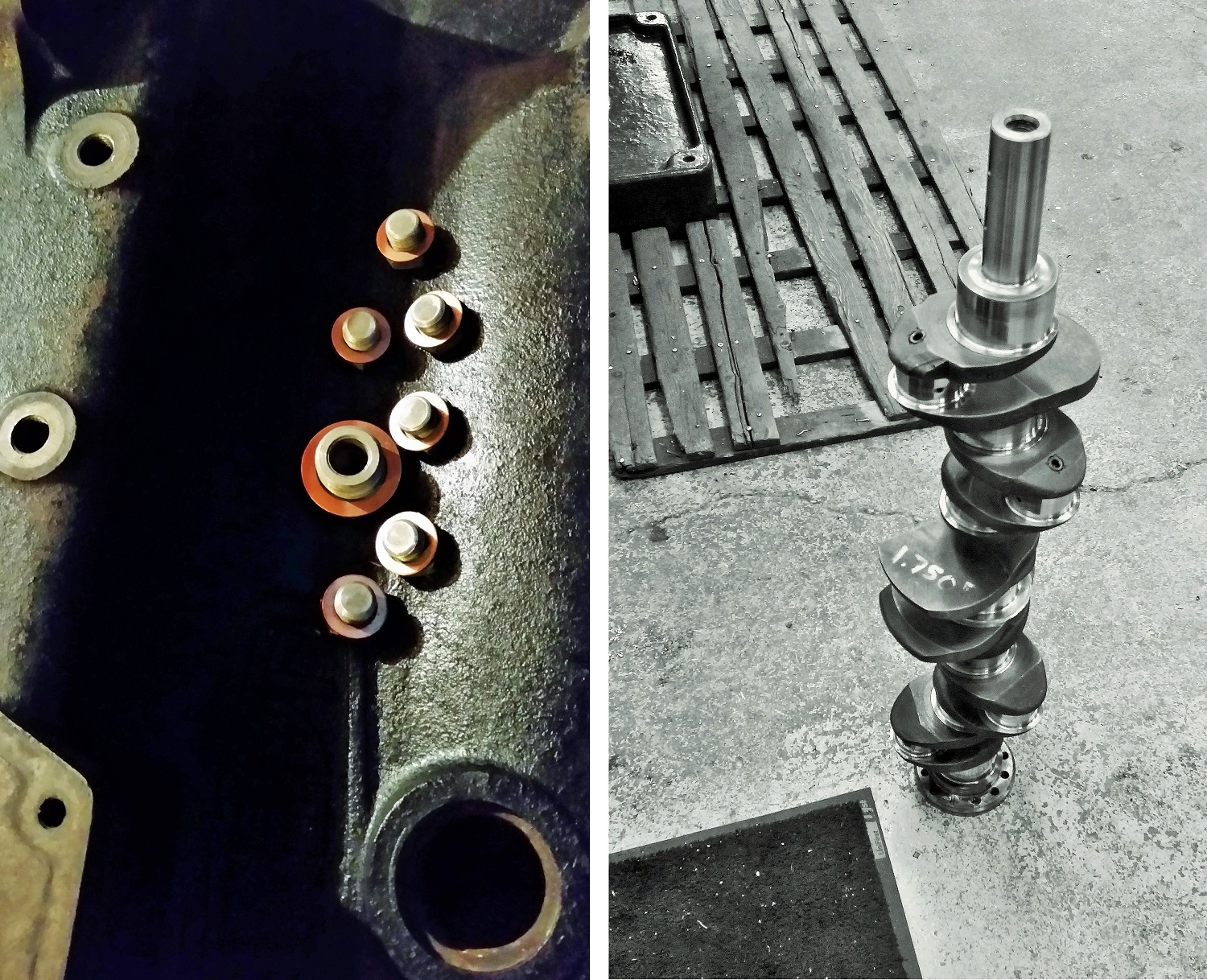

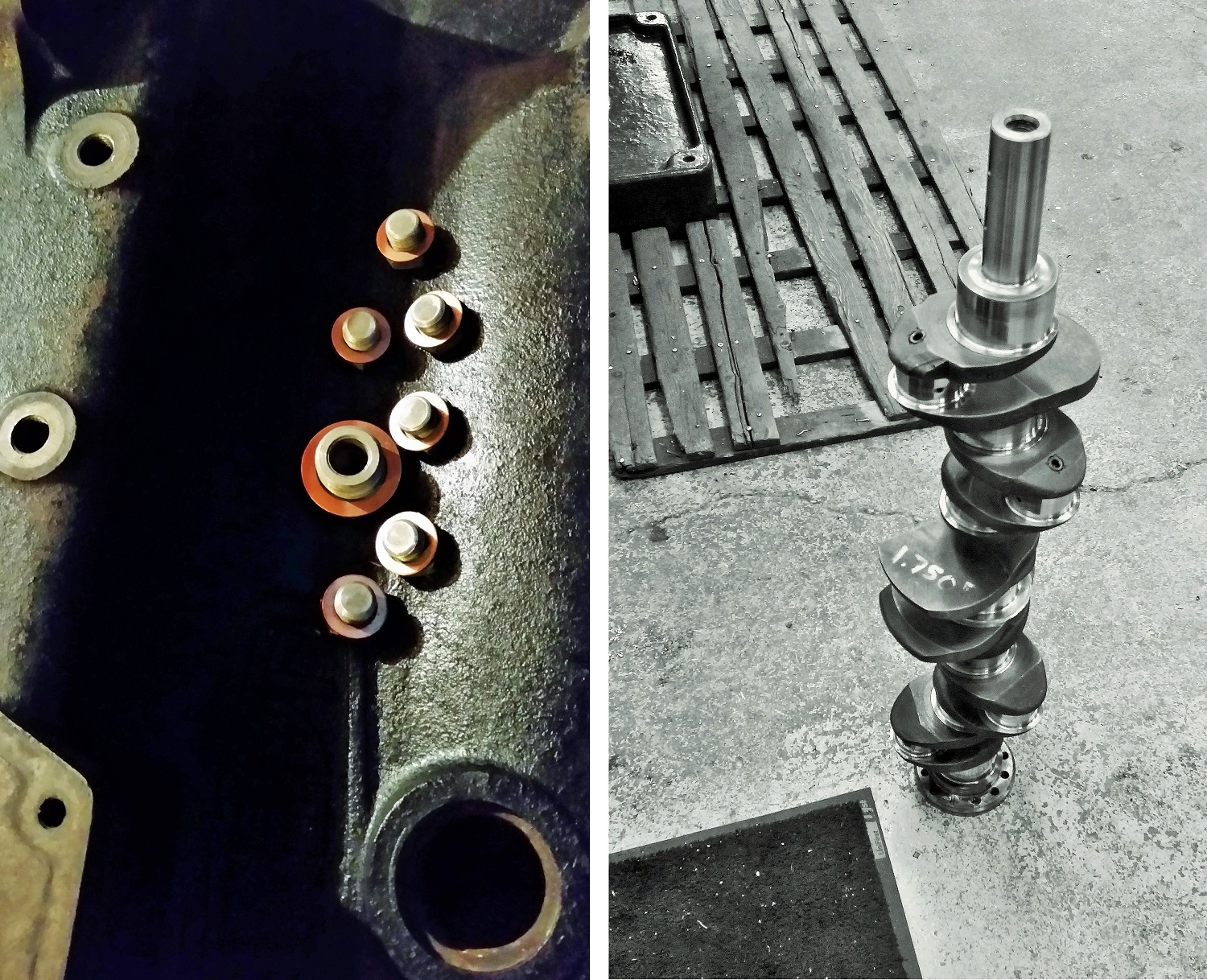

Scenes from the rebuild of a 3.8-liter E-type XK engine

On the left the plugs for the oil gallery on the lower right-hand side of the block have been removed for inspection and cleaning of the block.

The core plugs have also been removed, as seen in the lower right-hand part of the picture.

On the right the crankshaft is standing in shop, waiting to be picked up after machining work.

|

|

|

|

|

|

MG TC in a crowd

An early post-war MG car at an evening car show. This car was in production during the time of the XK-120.

|

|

|

|

|

|

|

|

|

|

Passenger in a Mercury

At another car show with mostly American cars, and only one E-type.

|

|

|

|

|

|

E-type Jaguar parked on the street

Fall scene of an E-type sitting.

|

|

|

|

|

|

|

|

|

|

View of the back of a Series 1 or 2 steering wheel

One of the exceptionally beautiful parts of the E-type, this aluminum steering wheel is in the initial stages of being refinished. In its Series 1 guise, it would have been polished, as this one is planned to be.

This is one of the many parts that seem to be described by Peter Egan in the May, 1997 Road & Track: "The car seemed to have a hundred individual parts you'd gladly display in a trophy case; it was a virtual mother lode of future paperweights, conversation pieces, heraldic wall hangings and Druidic totems, all compacted into a single kinetic object of amazing sensuality and grace."

This observation applies well to most of the parts shown on this website.

Some other pictures of the E-type steering wheel on this site can be seen:

here (with an aftermarket leather cover),

here (an early-style wheel undergoing wood refinishing),

here, (steering wheel on dash),

here (an early-style wheel damaged from an accident),

here (rear view),

here (another steering wheel on dash),

here (an early-style wheel in original condition on dash),

here (a restored later-style wheel),

and here (close up of the original finish on an early-style steering wheel).

|

|

|

|

|

|

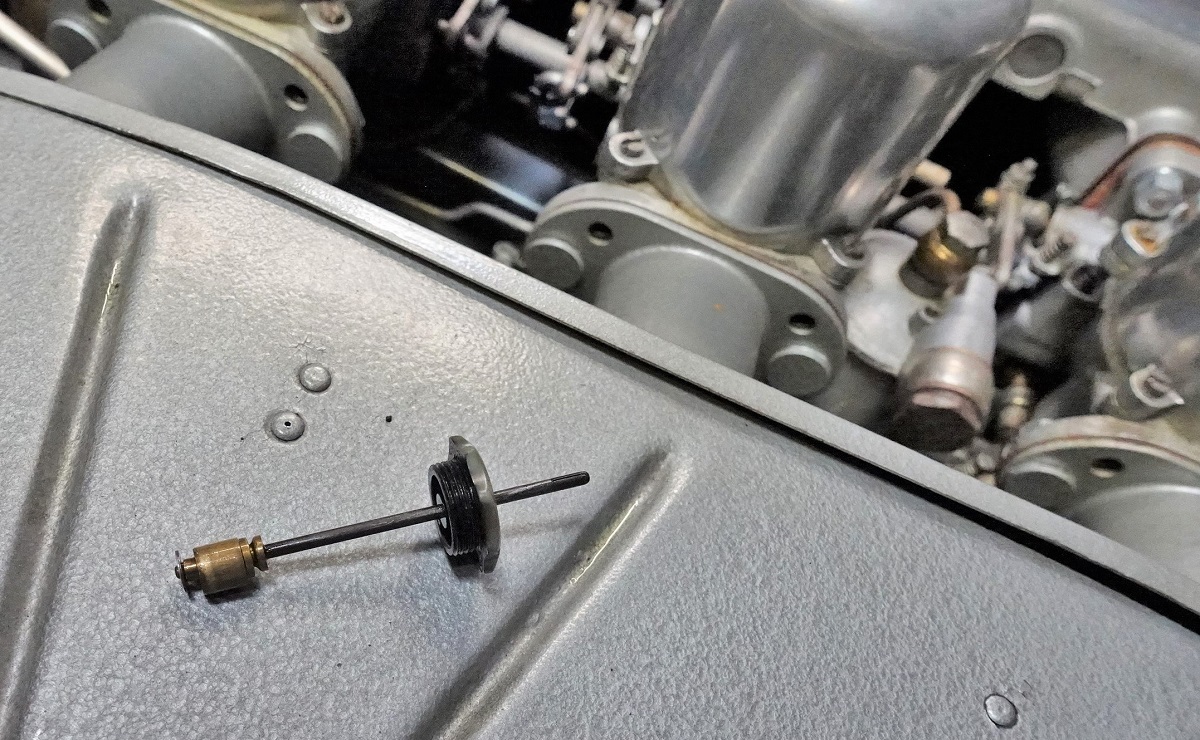

Broken damper assembly

This late-style damper assembly from a HD-8 S.U. carburetor was removed from a Series 1 two-seater coupe just after its failure had been discovered.

The plastic top had broken, permitting the damper rod to push through the top. The damper assembly (on the lower left in the picture) then pushed the rod up, and this was was noticed by the owner.

This is a relatively common failure mode for the plastic-topped dampers. The plastic design appeared on E-type HD-8 carburetors in mid-3.8-liter production, replacing the earlier brass tops. The plastic tops were introduced on other S.U. carburetors at about the same time.

The brass tops used on earlier E-types do not show this failure mode.

|

|

|

|

|

|

|

|

|

|

Water pump

This water pump has just been removed from a 3.8-liter XK engine and is still wet with anitfreeze. The back side of the round impeller is seen, with the end of the waterpump driveshaft in the center.

The curved path in the housing for the cooling liquid (propelled out from the impeller as it is spun by the driveshaft) wraps around the impeller, and ends on the left-hand side of the picture. The channel terminates over a rectangular aperture in the timing-chain cover, into which the cooling liquid then flows. From there it enters a long channel running along the top left side of the engine block, and then flows into the cooling jackets.

|

|

|

|

|

|

Dash plaque on the last E-type

The last E-types produced (V-12 Series 3 cars) carried commerative plaques. The very last E-type produced carried this special plaque.

This is a similar-looking plaque to those used on early XK-120 roadsters (except the first few), and on XK-140 roadsters, describing their performance.

|

|

|

|

|

|

|

|

|

|

Front-view, Series 1 E-type

A nicely-restored car sitting on the grass at a concourse.

|

|

|

|

|

|

"STOP ENGINE WAIT 1 MIN"

The dipstick of the Series 1 and 1.5 cars is yet another example of the fundamental high quality of the E-type.

This unit is comprised of many pieces brazed together (and for early cars, also riveted) and chrome plated.

The handle at the top, shown here, is cast from bronze or copper. It was then chrome plated, along with the rest of the assembly, hiding the expensive underlying material.

Similar examples of hidden high-quality material are also found in the instruments, window trim, carburetors, and other places. This is one example of the understated quality of the E-type that was at the same time a relatively inexpensive car. Lyons was a master at achieving both these qualities in the classic Jaguars.

|

|

|

|

|

|

|

|

|

|

Dawn seen down the bonnet . . .

. . . as this E-type is warmed up for the day's drive.

|

|

|

|

|

|

Checking the oil during a fuel stop

Though introduced over five decades ago, checking the oil on an E-type during fueling is still a dramatic scene.

|

|

|

|

|

|

|

|

|

|

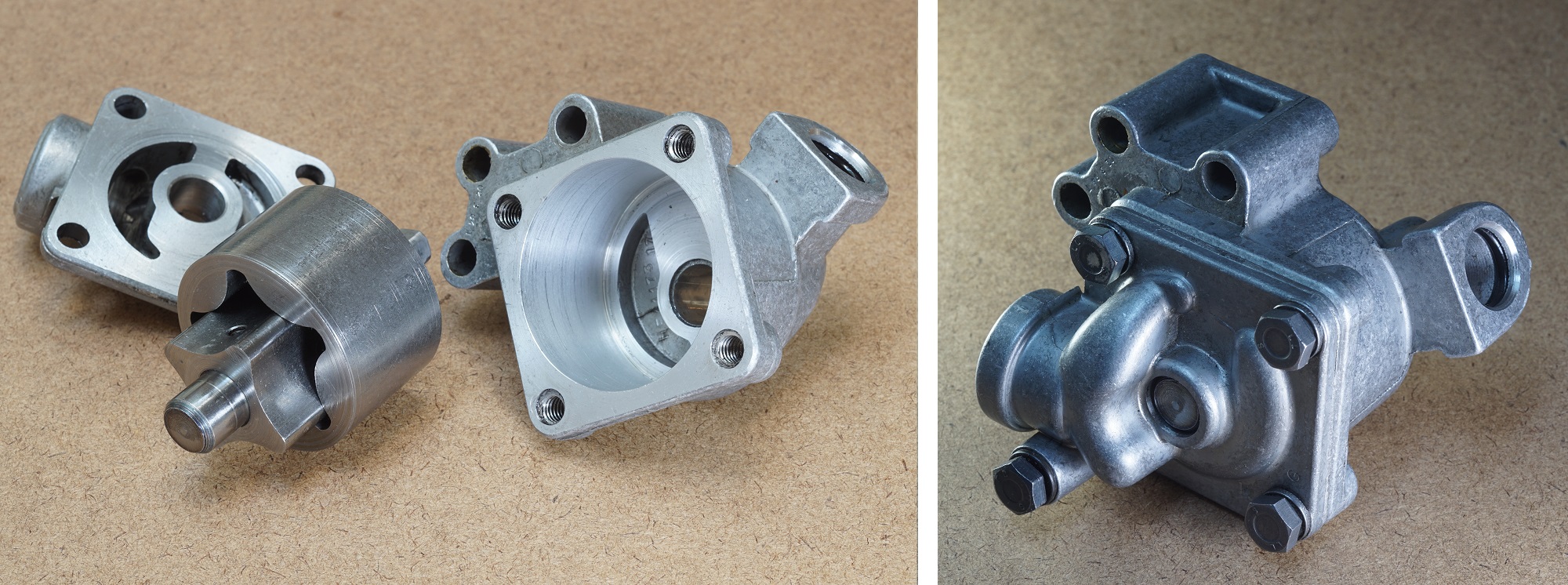

XK-engine oil pump

This pump is from the era of the E-type; different styles of pumps were used during the long production period of the XK-engine.

On the left the pump is seen dissembled, while the assembled unit is seen on the right.

|

|

|

|

|

|

Austin Healey 100

The initial 4-cylinder Austin Healey was generally known as the "100-4" after the introduction of its successor, the "100-6."

These early cars had a fold down windshield, as did some other English sports cars of the period. This one, however, slanted back as opposed to folding down toward the front of the car.

This car was introduced during the early 1950s when Jaguar was producing its XK-series sports cars.

It later evolved into the "3000" model, also 6-cylinders, that was a contemporary of the E-type up to 1967.

|

|

|

|

|

|

|

|

|

|

Jaguar SS-100 roadster

This car, along with its direct predicessor the SS-90, represented the first true sports car produced by Jaguar Cars (then with its name as SS).

This was the first of the lineage that led to the E-type (along with the side brances of the C- and D-type competition cars).

|

|

|

|

|

|

Shift knob on Moss gearbox

This original 3.8-liter type shift knob is on a Moss gearbox in storage.

This beautiful knob, with the pattern on the inside of a clear dome on the top, was the earliest type used on E-type Jaguars.

|

|

|

|

|

|

|

|

|

|

Counterbalance spring mechanism.

This unit is broken, as often happened. It has already had an earlier repair.

This design was replaced during Series 2 production with a gas-filled cylinder.

|

|

|

|

|

|

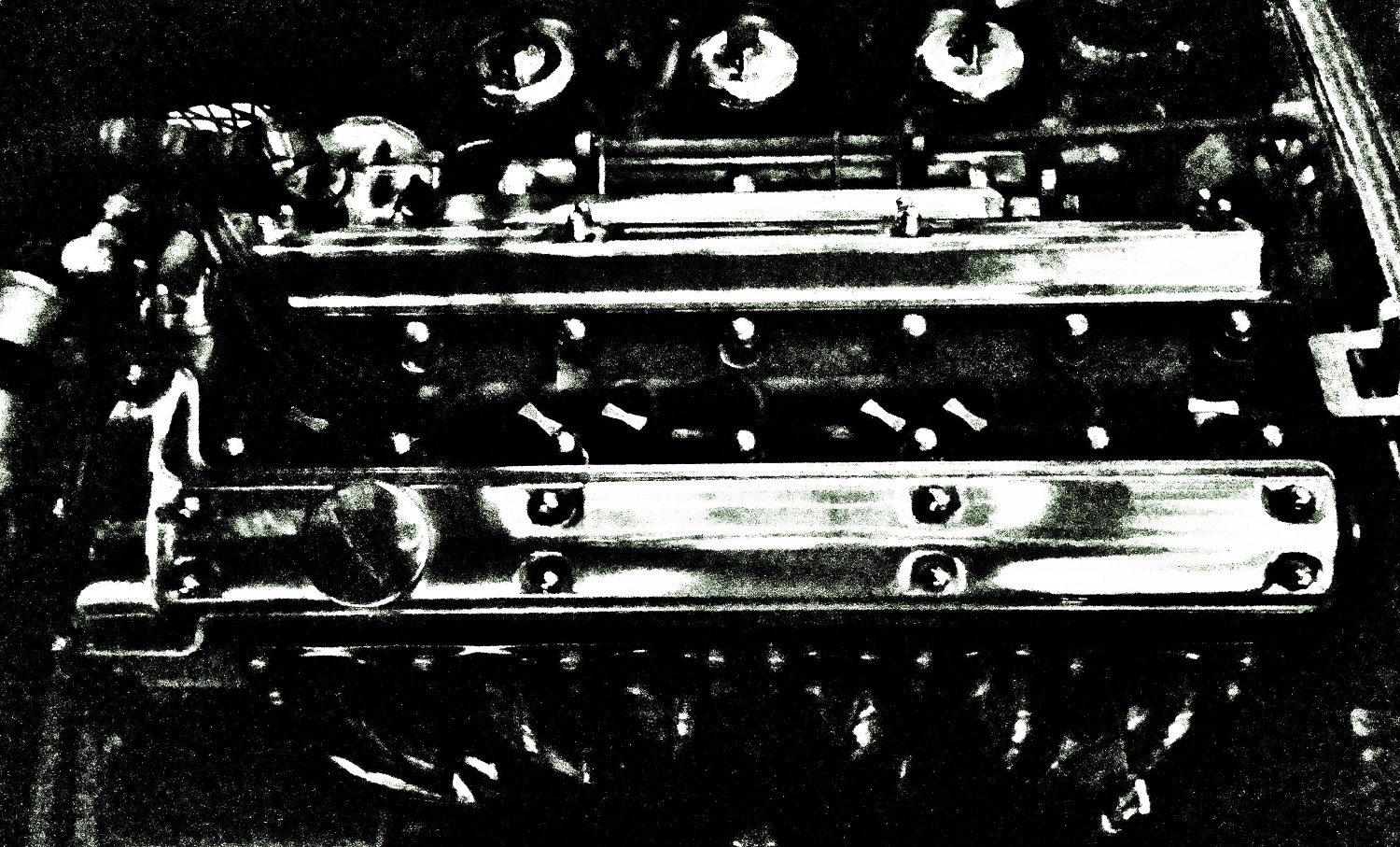

Left-hand side view of the S-type XK engine, as fitted to the E-type Jaguar

View of the polished aluminum cam covers, intake manifold components and S.U. HD-8 2-inch throat carubretors.

Although it was over ten years old in 1961 when the E-type was introduced, it was still an advanced design for the day.

|

|

|

|

|

|

|

|

|

|

Choke cable adapter

This small part attaches the end of choke control cable to the choke control rod on the bottom of the center carburetor.

It is one of hundreds of attractive small details that make up the E-type Jaguar.

|

|

|

|

|

|

Top of the timing chain assembly

The intermediate gear tensioner is in the top of the picture.

In the top left of the picture the West Yourkshire Foundry mark can be seen in the cast aluminum.

|

|

|

|

|

|

|

|

|

|

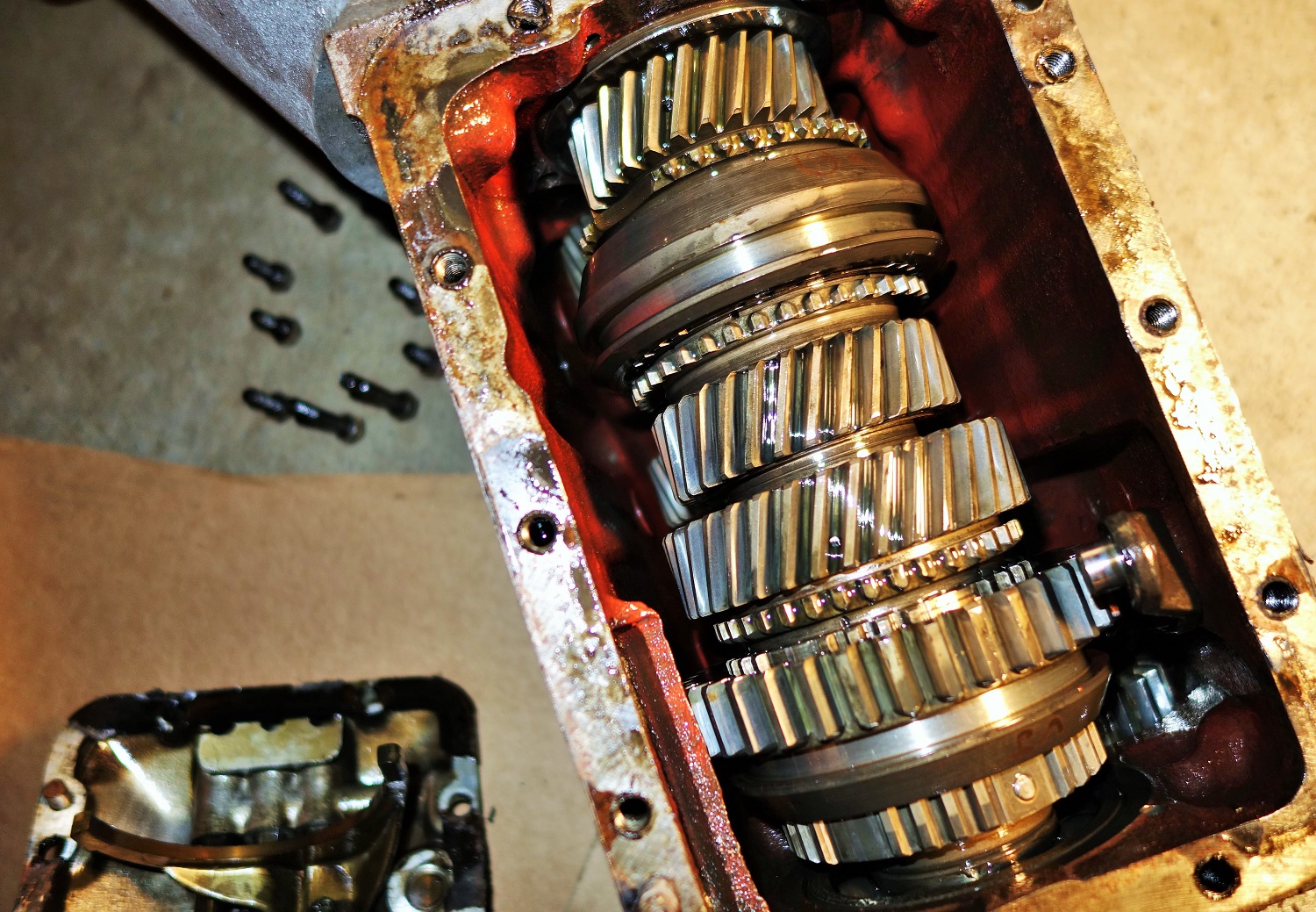

Moss gearbox with cover removed

The gears had just been turned before removal of the cover. Oil can be seen seeping back down in to the case.

|

|

|

|

|

|

Right rear view of a Morgan

These cars were in production at the same time as the E-type.

Perhaps they represented the opposite pole from the E-type.

|

|

|

|

|

|

|

|

|

|

Alloy-body XK-120 NUB 120

This fameous car is on display at the Gaydon facility.

|

|

|

|

|

|

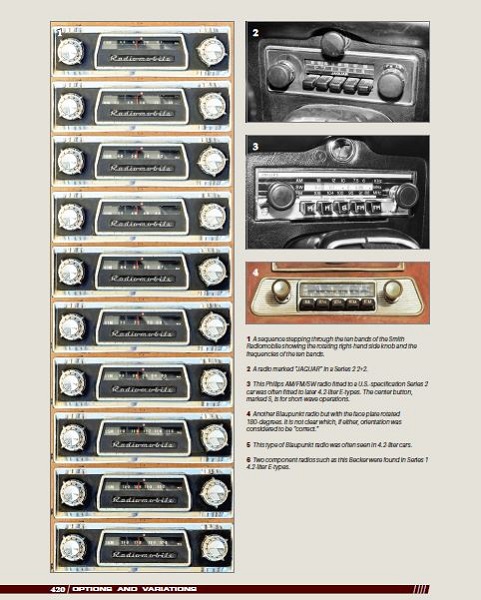

Discussion of radios in the new originality book

This is a view of page 420 of the new book. The series of pictures on the left shows the selection of many different bands on a Smiths 530T "Wave Change" radio.

The drum position is set by turning the rear knob on the right.

|

|

|

|

|

|

|

|

|

|

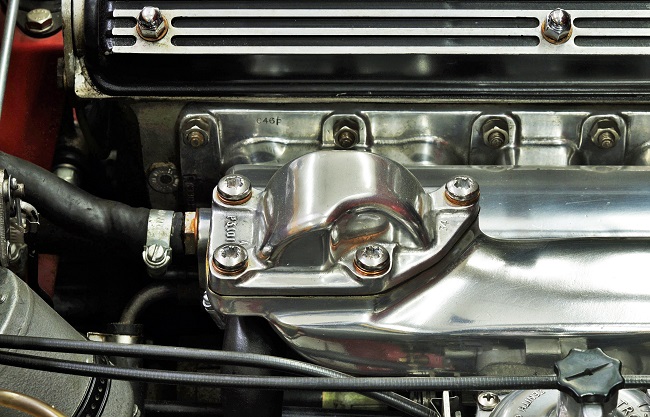

A later stage of a Series 2 intake manifold

This aluminum cover replaces the crossover pipe used on earlier U.S. emission control cars.

The finned cam covers introduced with the Series 1.5 cars is seen at the top of the picture.

|

|

|

|

|

|

T-key cover escutcheon

These spring-loaded covers were positioned over the T-key holes on the first 500 E-types produced.

The covers were delicate, and often broke off.

They were also used on Triumph cars and Jaguar Mk V sedan fender skirts. XK-120 fender skirts had simlar covers, but they were round in shape and less ornate.

|

|

|

|

|

|

|

|

|

|

Lucas distributor

This distributor is missing its cap and contains debris from long storage.

The screw-on vacuum-advance line is missing here.

|

|

|

|

|

|

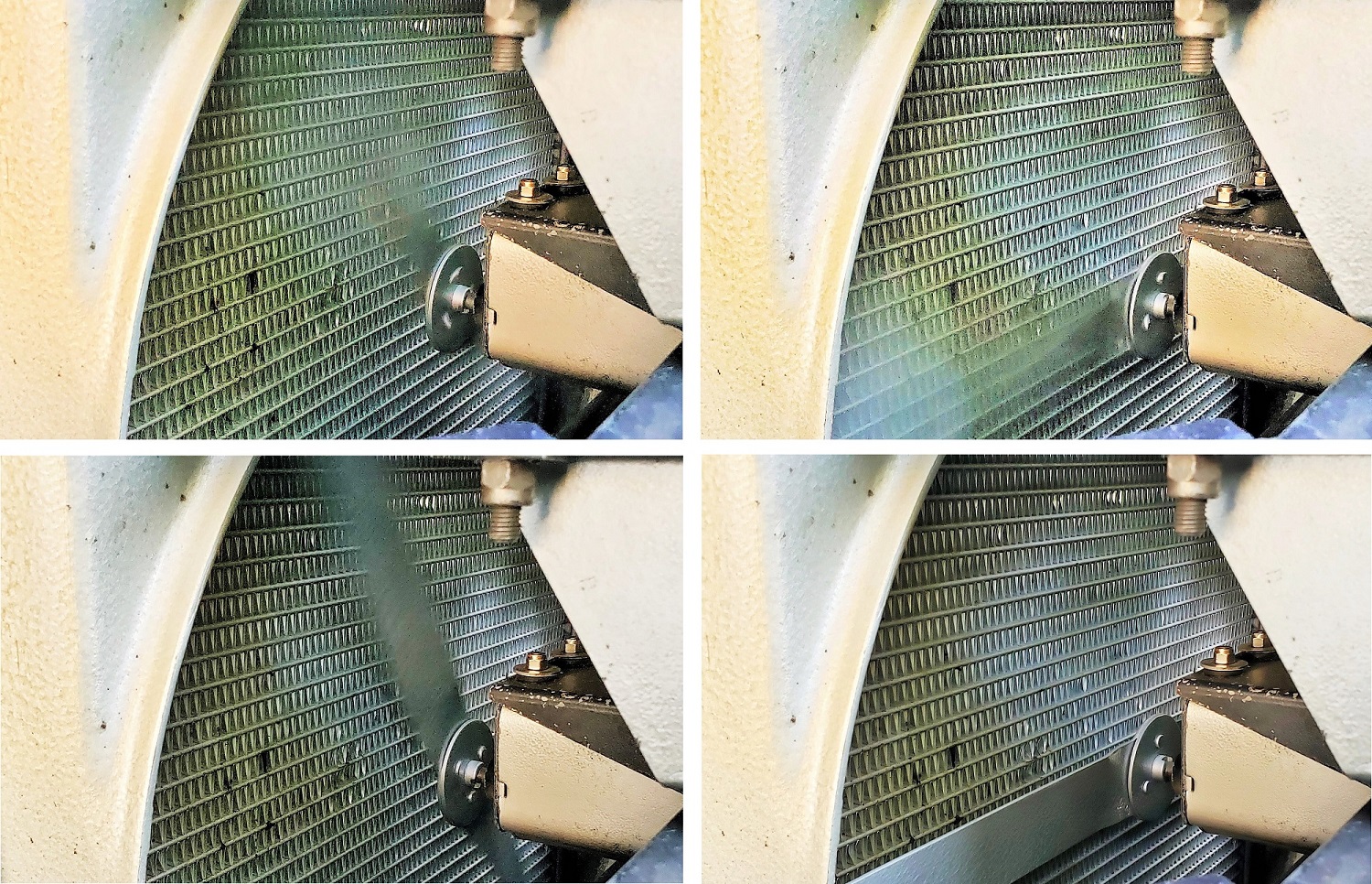

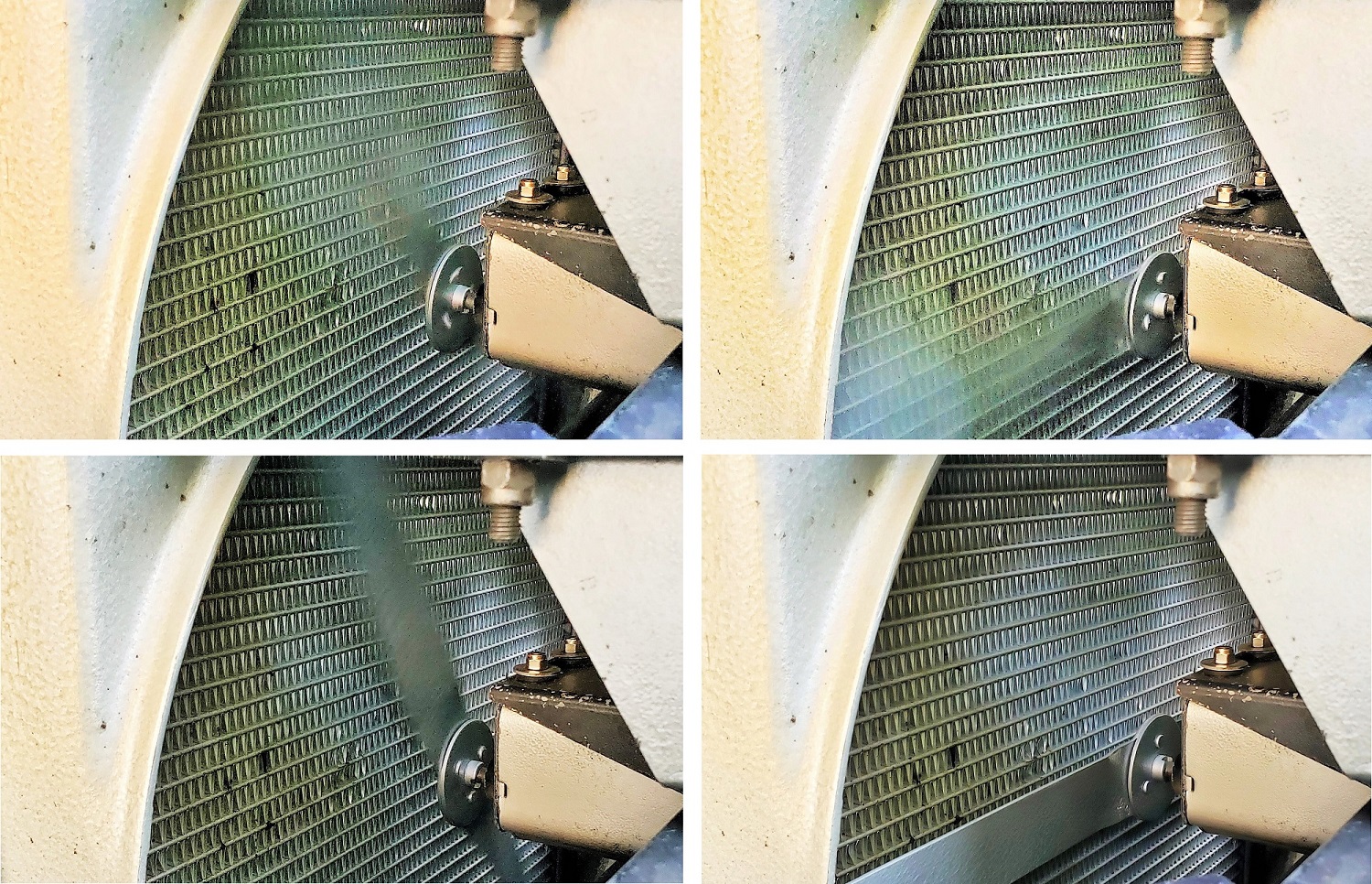

Aluminum crossflow radiators

The early E-types had aluminum crossflow radiators.

By the time of 4.2-liter production, the radiators were made of brass. Brass was the material of other post-war Jaguars up to 1961.

Not many of these original aluminum radiators are still in service. They are collector's items in their own right.

|

|

|

|

|

|

|

|

|

|

3.8-liter XK engine crankshaft

The 3.8-liter XK engine crankshafts had wider central main bearing journals than the subseuqent 4.2-liter engines.

This accomodated the closer cylinder spacings of the 4.2-liter engines.

|

|

|

|

|

|

Another view of late-type 3.8-liter aluminum dash trim

The cross pattern aluminum trim on this later 3.8-liter car is in excellent condition.

It seems this cross-pattern aluminum finishing is not yet available as a reproduction. Reproductions of the earlier dot-pattern aluminum trim have been available for some time, although generally they do not accurately resemble the original.

The keys are not originals.

|

|

|

|

|

|

|

|

|

|

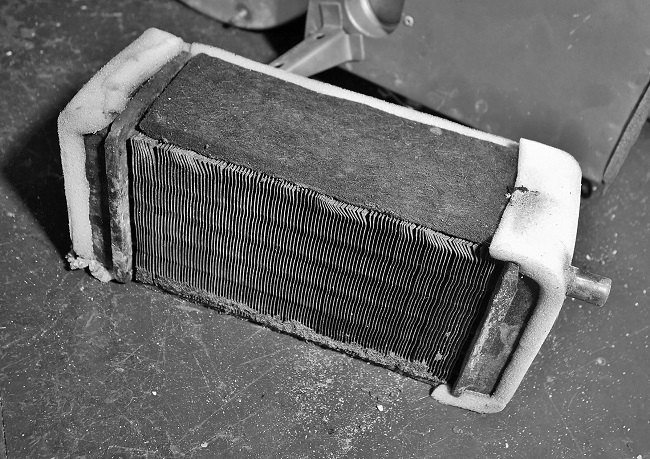

Heater core

The heater core is a small radiator housed in the heater housing bolted to the left front of the firewall.

While the 3.8-liter cars were fitted with aluminum radiators, these small cores were made of brass.

|

|

|

|

|

|

Sunbeam Rapier with rust

Just like E-type roadsters, this Sunbeam has rusted in two.

Unlinke the monocoque E-type, however, this car has a ladder frame.

It still rusted in two.

|

|

|

|

|

|

|

|

|

|

Modern Jaguar

. . . parked on the street in the West Midlands.

|

|

|

|

|

|

E-type Jaguar

An operable black E-type roadster.

|

|

|

|

|

|

|

|

|

|

Front belt pulley

The early pulleys were of the single-grooved type. Later on in 3.8-liter production a double-grooved pulley was used.

This one is aluminum; the later were made of steel.

|

|

|

|

|

|

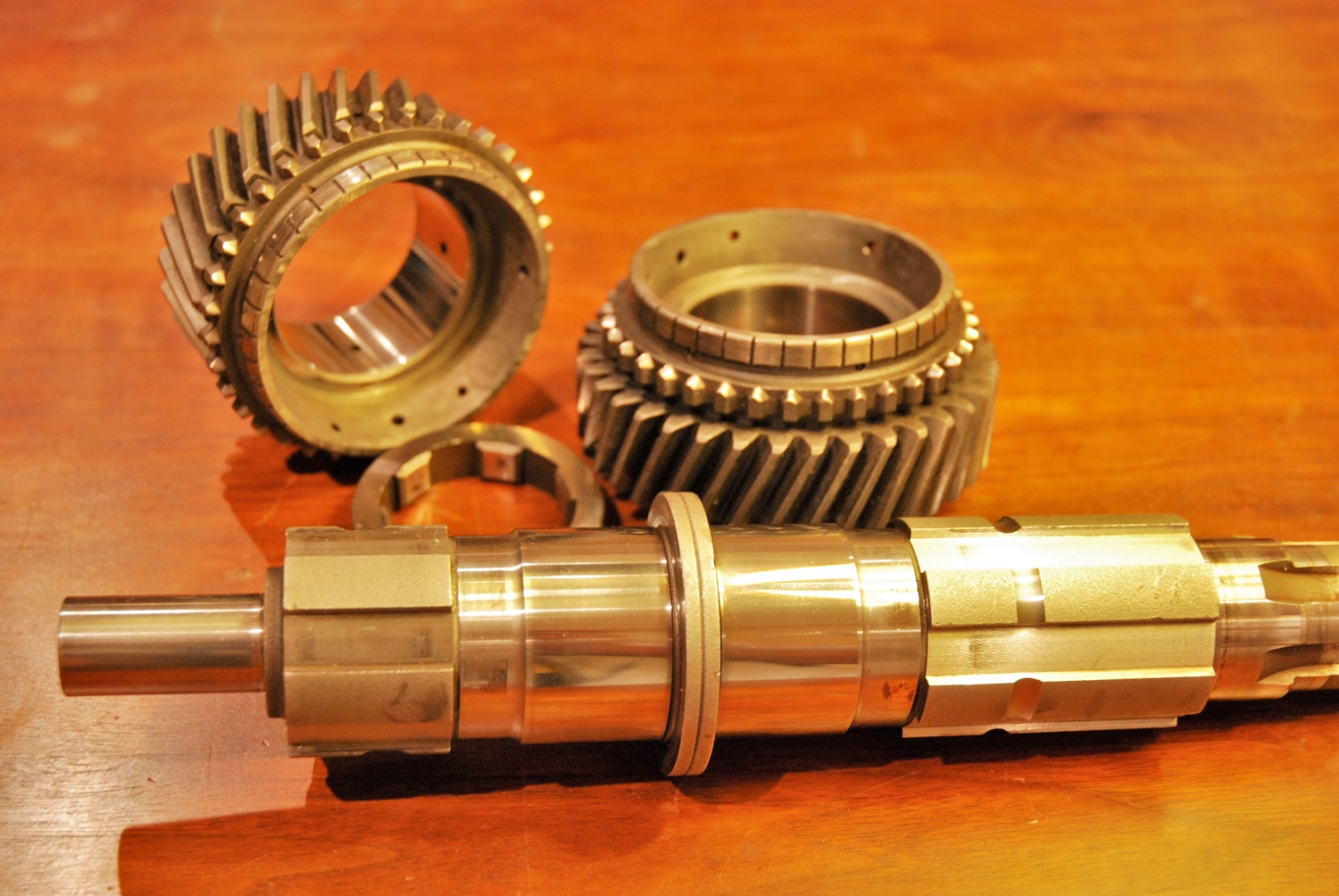

First and second gears of a Moss gearbox

The first and second gears show half the synchronizing cones.

While both these gears, as well as top gear, were technically synchronized, the system was not very effective, at least by modern standards. Double clutching for downshifts on these gearboxes is a good idea.

While these gearboxes used in 3.8-liter E-types are referred to as "Moss gearboxes," by this time they were actually made by Jaguar.

The new synchronizing system that came in with the 4.2-liter E-types used balk rings, and was much more effective. It also had forced lubrication.

|

|

|

|

|

|

|

|

|

|

XK engine cylinder head

The XK engine used a hemi head. This is the face side; the top had polished aluminum cam covers.

The face of this aluminum head has just been resurfaced.

|

|

|

|

|

|

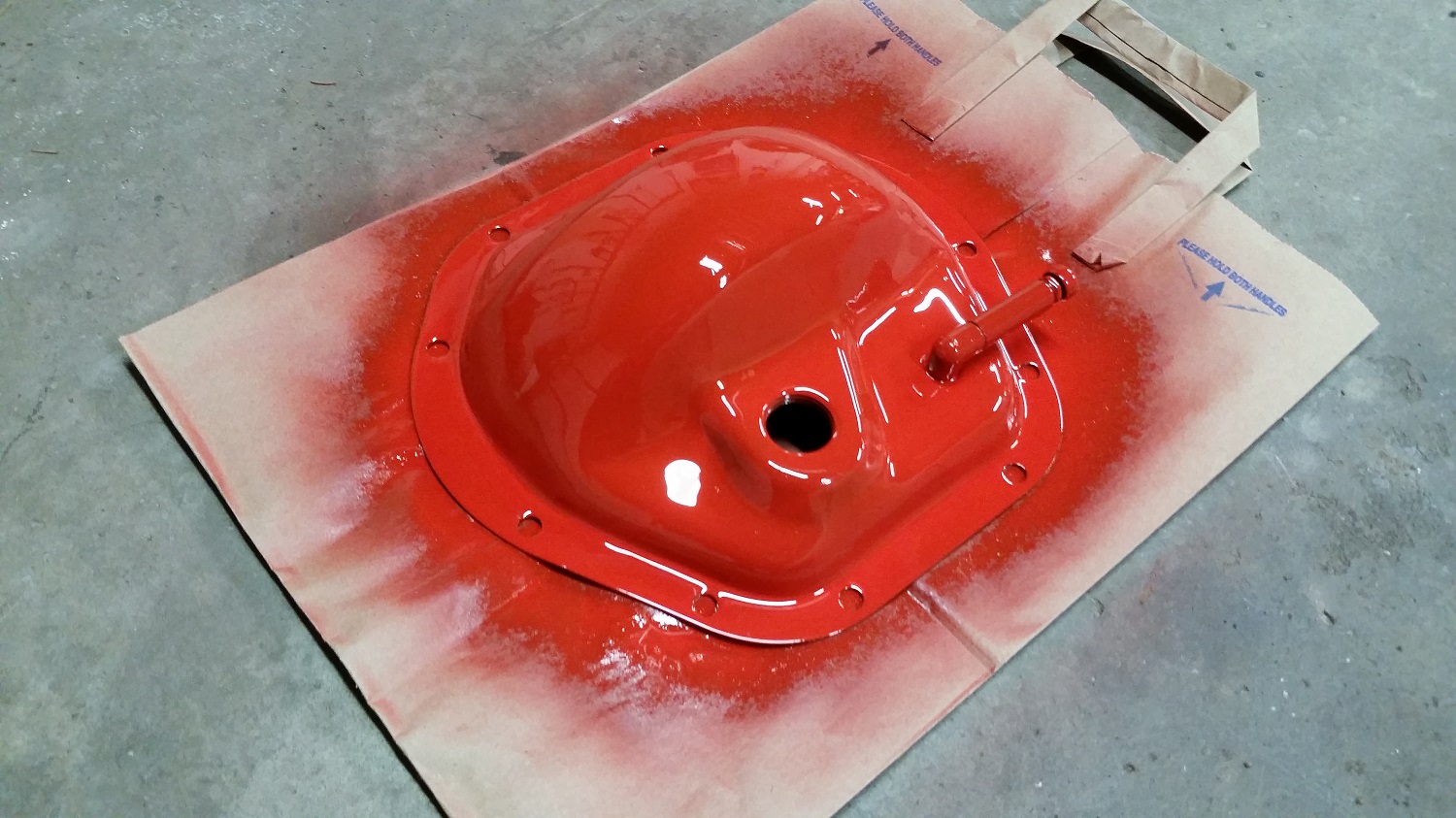

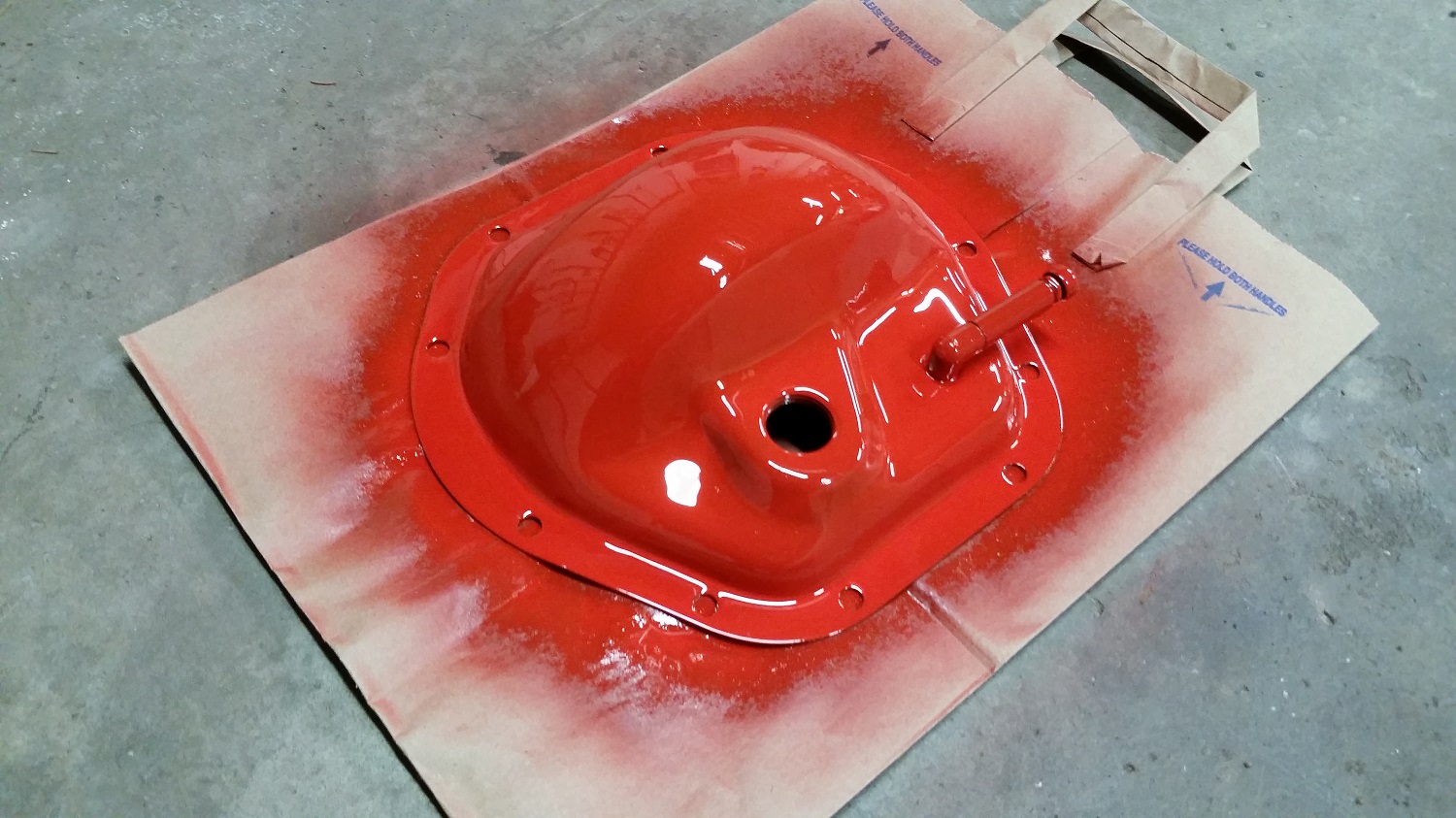

Differential cover

. . . repainted on a grocery bag.

|

|

|

|

|

|

|

|

|

|

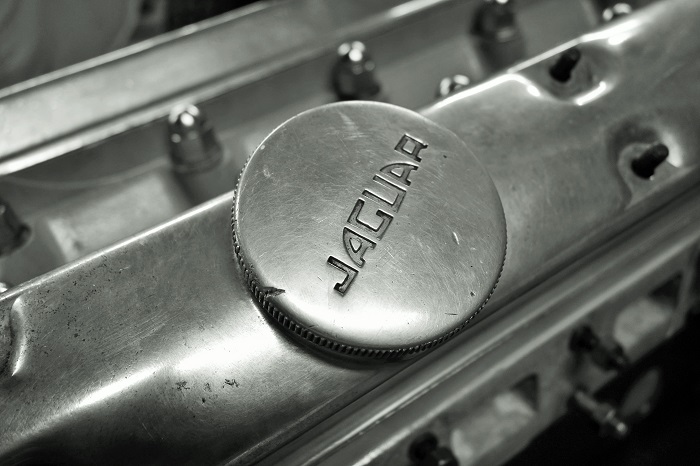

Traditional XK-engine oil filler cap

From the 1940s to 1970s all XK engines were fitted with this lovely polished-aluminum oil-filler cap.

Later in XK-engine production the name "JAGUAR" was left off the cap.

|

|

|

|

|

|

Jaguar Mk 2 sports sedan in blue

Introduced a couple of years prior to the E-type, this second-generation continuation of the Jaguar sports sedan series continued the traditional post-war Jaguar styling.

The E-type was a complete break with the production Jaguar styling, carrying the racing D-type style to Jaguar's production cars.

Note also here the leaping cat mascot that was used on some Jaguar sedans; this feature was never included on the XK-series or E-type sports cars.

|

|

|

|

|

|

|

|

|

|

Mercedes Benz parked in a field

This Mercedes shared the fate of many classic cars, including many E-types.

|

|

|

|

|

|

Behind the glovebox

This view of an E-type is not usually seen. Often one of the last remaining areas of originality on an old car, this view shows the defroster hoses and some of the trim glue over the origanial white paint.

This area is usually preserved by all but a full restoration.

|

|

|

|

|

|

|

|

|

|

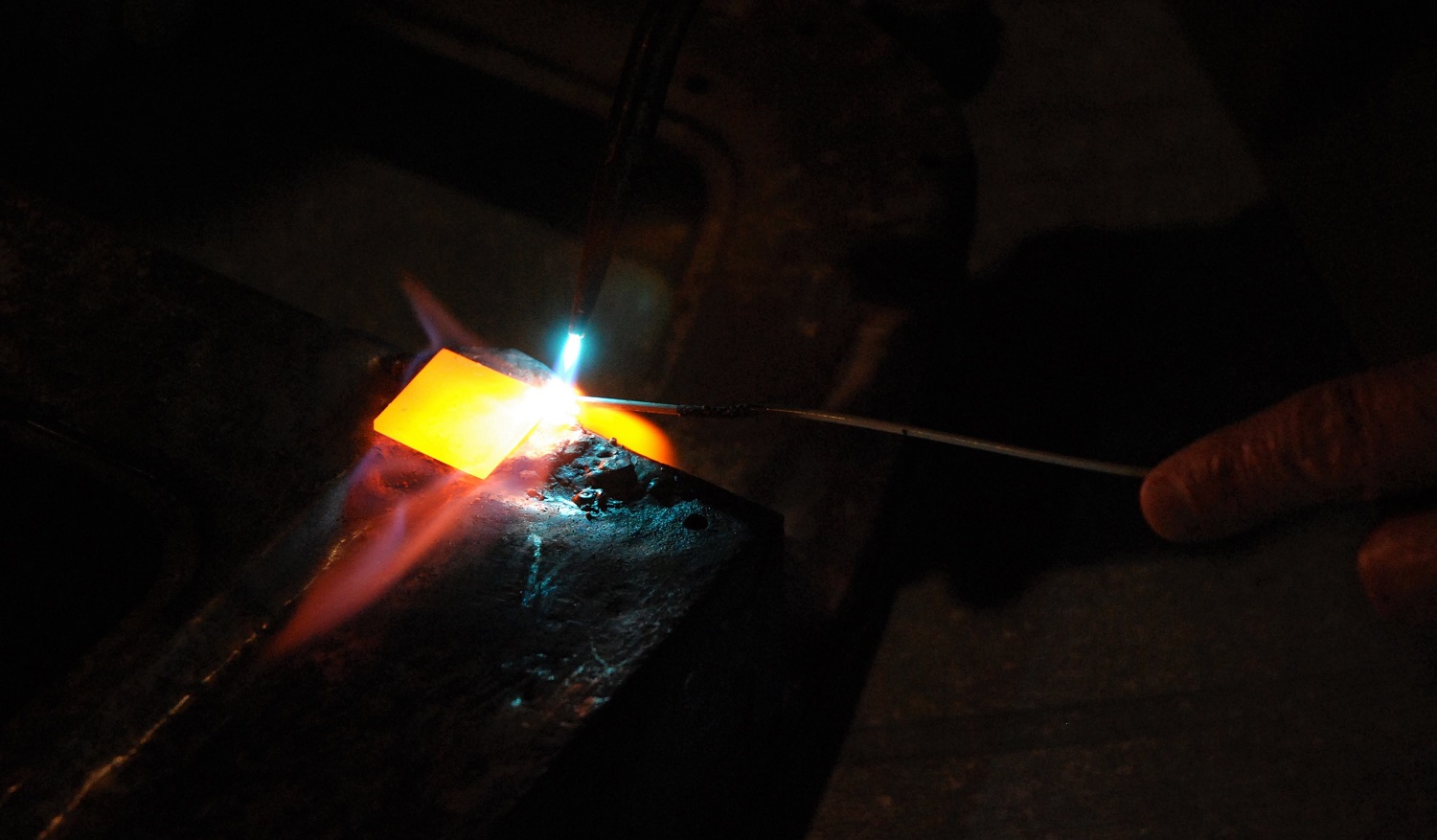

Rust repair

Here a rusted-out seat frame is getting welded up.

Almost any area of an E-type was subject to rust.

|

|

|

|

|

|

MGA

Dash view of this MGA shows the wire-spoke steering wheel used on many British cars during the period of the E-type.

The E-type's drilled-out aluminum wheel was the exception.

|

|

|

|

|

|

|

|

|

|

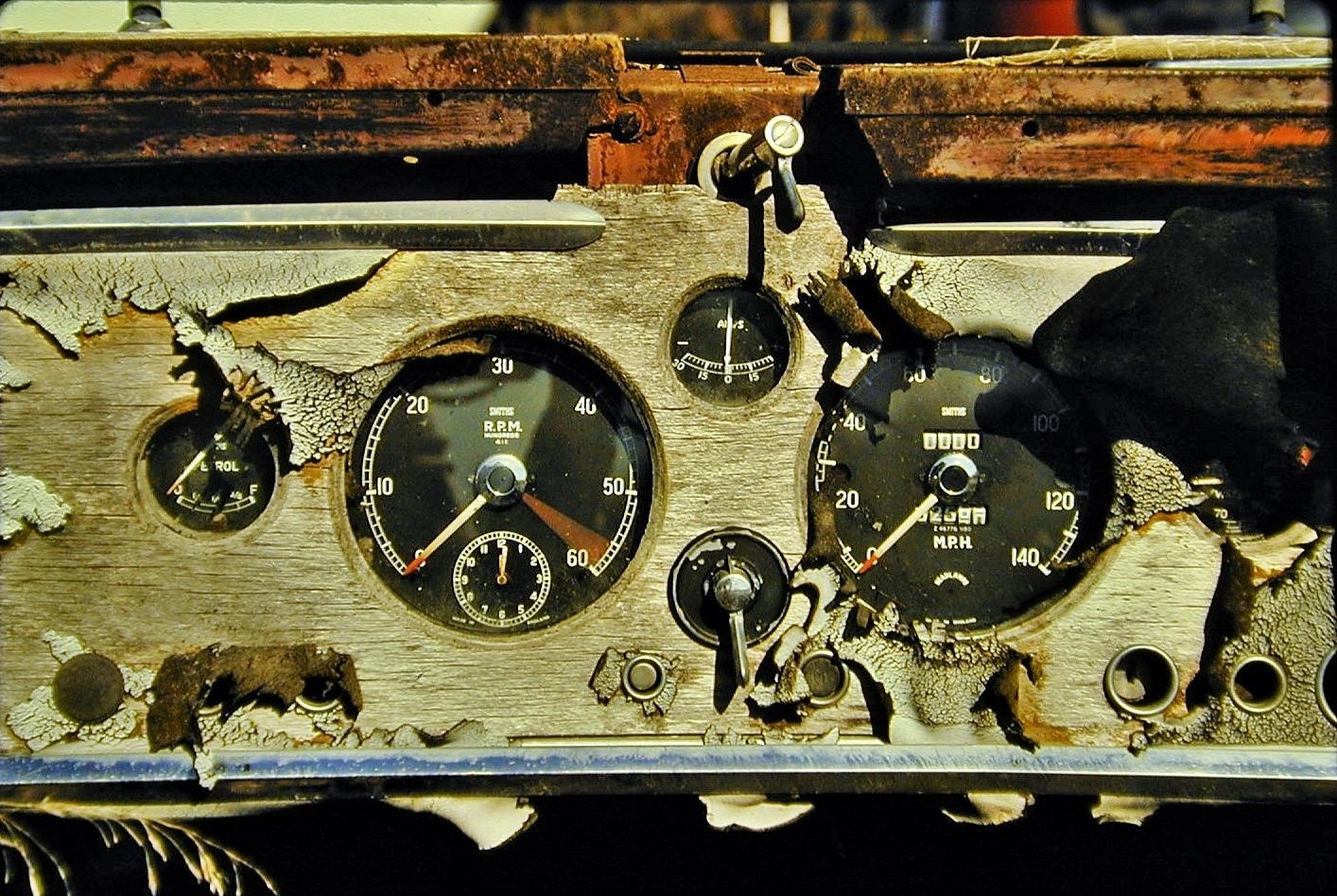

XK-150 dashboard

In keeping with the rest of the XK series, the main instruments were located in the center of the XK-150's dash.

The roadsters, such as seen here, had a leather covered dash. Here some of the leather is missing, showing the wooden frame below.

|

|

|

|

|

|

Early-style Series 1 steering wheel during rework

This rear-view of an early Series 1 (thick crossection) steering wheel during refinishing shows the irregular pattern of the thumb grooves.

Note that there are several sections where the thumb groove pattern is interrupted by an exceptionaly wide groove spacing.

On later wheels the thumb groove spacing was regular, at least between the spoke attachment points.

Bare unfinished wood is seen on this wheel.

|

|

|

|

|

|

|

|

|

|

Rear inboard brake caliper

Inboard rear disc brakes were one of the exceptionally-advanced technological features of the E-type.

Even today, this is still advanced technology.

|

|

|

|

|

|

Racing mirror on E-type roadster

Mirrors such as these were common in the 1950s and 1960s, and were found on many E-types.

It is likely more than half of the E-types in the U.S. were fitted with mirrors similar to this one.

|

|

|

|

|

|

|

|

|

|

Early E-type intake manifold and head

When the E-type was first introduced the spark-plug caps had this round-top CHAMPION design, the cylinder head paint was a pumpkin color, and the carburetor linkage was comprised of this rather complex arrangement of seperate levers.

The basic appearance, though was fundamentally unchanged from 1961 to 1967, with the polished aluminum componentry as used on all XK-engined Jaguars from 1948 onward.

In 1968, coincident with the implementation of the modifications to comply with the U.S. vehicle safety and emissions requirements, the prinicpal the main polished aluminum component, the cam covers, were changed to a finned design.

|

|

|

|

|

|

XK-150

The XK150, the direct predecessor of the E-type, was of the traditional XK-series design. It carried much more chrome trim than the E-type, as well as bumper protection for U.S. parking conditions.

It was also a much heavier car.

|

|

|

|

|

|

|

|

|

|

Lincoln

This view down the hood of a 1960s Lincoln Contentinal shows the squared-off body style and especially large size of U.S. cars marketed during the period of production of the E-type.

|

|

|

|

|

|

Amco walnut shift knob

These shift knobs were a popular aftermarket accessory for sports cars in the U.S. market in the 1960s and 1970s.

This one has an enamel Jaguar emblem on it, in a style somewhat similar to the E-type horn button design.

These were available from vendors such as Vilem B. Haan and MG Mitten, who ran advertisements in sports car magazines and offered catalogs of accessories.

|

|

|

|

|

|

|

|

|

|

Horn relay

This relay has its cover removed. It is stamped "11 62," indicating a Noveber 1962 manufacture date.

Here the cover has been removed and the coil can be seen, with the high-current contact seen on the right.

|

|

|

|

|

|

Needle bearings from Moss transmission

There are many needle bearings in the Moss transmission used in the 3.8-liter E-types.

|

|

|

|

|

|

|

|

|

|

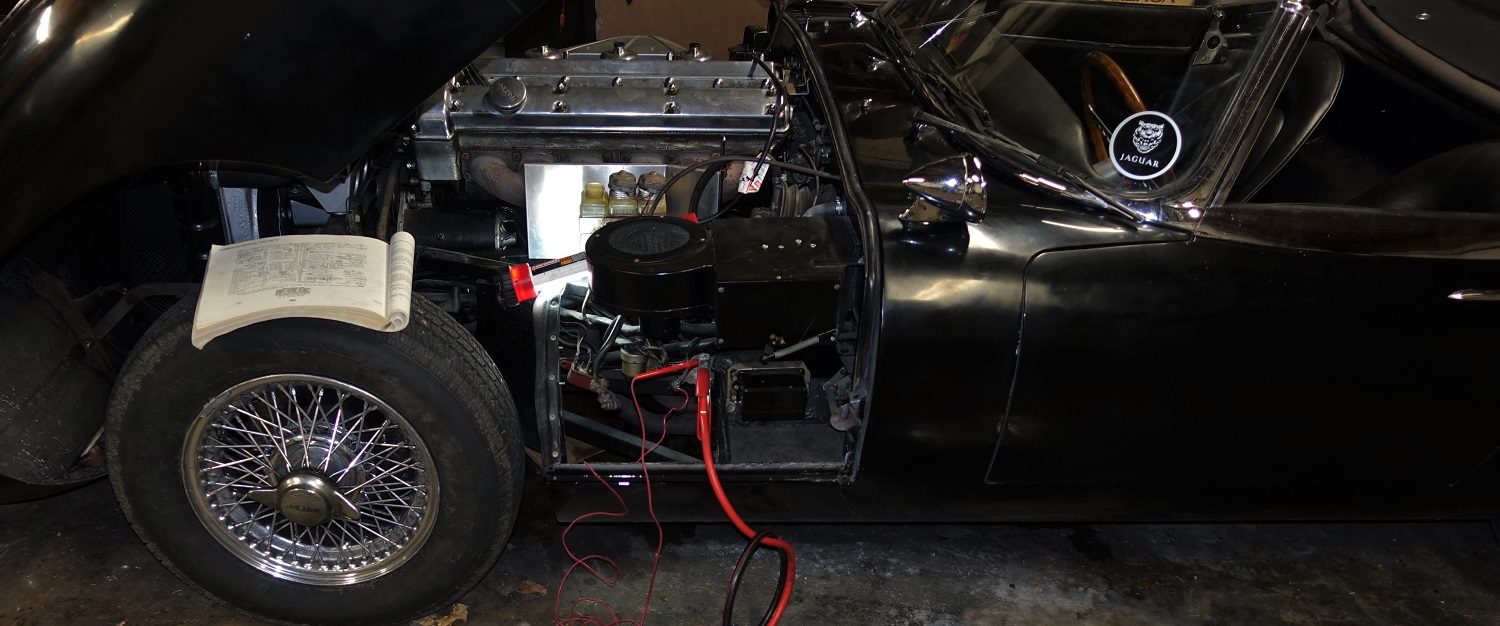

E-type undergoing repairs

Electrical repairs are being made with the Bentley manual showing the wiring diagram and sitting on the drivers-side wheel.

|

|

|

|

|

|

Faced-off block deck on 3.8-liter XK engine

Head studs and pistons have been replaced during this rebuild.

|

|

|

|

|

|

|

|

|

|

Later style Series 1 bonnet

Early Series 1 bonnets had the headlight nacelles in body color.

Later on during 3.8-liter production they were silver.

|

|

|

|

|

|

Hub cap and splined hub

This view of a rear wheel hub shows the beautiful cast hubcap.

The brass material used for the casting was finished with polished chrome plating. In the understated manner found throughout the car, the expensive material is not even displayed.

The name "JAGUAR" is cast into its face (unlike most cars of the era that carried anonomyous hubcaps).

Also especially notable in this picture is lack of a brake at the hub; rear brakes were mounted inbord.

|

|

|

|

|

|

|

|

|

|

XK engine crankshaft

This view of the seven main bearing crankshaft from a 3.8-liter E-type engine clearly shows the sturdiness of the design.

|

|

|

|

|

|

Limited-slip differential

View of the internals of the Series 1 E-type differntial.

|

|

|

|

|

|

|

|

|

|

Series 1 E-type roadster

. . . just rpior to driving.

|

|

|

|

|

|

Magritteian view from passengers side of a Series 1 E-type

View down the road at dusk.

|

|

.jpg)

|

|

|

|

|

|

|

|

Timing gear and cover from XK engine

Some of the components from the complex and clever timing gear system used on all XK engines.

|

|

|

|

|

|

Rear subframe emerging

The rear subframe of an E-type contains the rear drivetrain, brakes and suspension in a compact unit that comes out as a single piece.

The rear disc brakes are mounted inboard. The whole unit is a beautiful peice of engineering.

|

|

|

|

|

|

|

|

|

|

Moss gearbox housing

The housing of the Moss gearbox is made from cast-iron. These gearboxes are very durable.

There were variations in these castings during 3.8-liter XK-E production.

|

|

|

|

|

|

D-type

Restored D-type sitting on grass.

|

|

|

|

|

|

|

|

|

|

MGA dash

The MGA, like most sports cars of the E-type's era, had chromed bezels around the instruments, in contrast to the E-type's matte black.

|

|

|

|

|

|

Generator from 3.8-liter E-type

This generator is of the later 3.8-liter type with a smaller outside diameter than the earlier generators.

The original generator color was a semi-gloss black as opposted to the reddish paint now on this generator.

|

|

|

|

|

|

|

|

|

|

Clutch and brake reservoirs

The later brake and clutch fluid reservoirs were rectangular in shape, as opposed to the cylindrical shape of the earlier reservoirs.

Another feature of later 3.8-liter cars is the elastomeric covers seen on the rg two (brake) reservoirs. These same covers were used on 4.2-liter cars.

|

|

|

|

|

|

View down the bonnet

All features of the E-type bonnet are fully functional; there are no decorative embellishments.

|

|

|

|

|

|

|

|

|

|

E-type in the late 1960s or early 1970s

An old picture showing an E-type sitting in the sun.

|

|

|

|

|

|

"E JAG" sticker

"E JAG" stood for "Eastern Jaguar Group," a club operating on the east coast of the U.S. and based in Westford, MA.

While the name suggests the club focused on E-types, it actually covered all types of Jaguars.

The club also had members from a much wider geographic range, but today appears to no longer be operating.

|

|

|

|

|

|

|

|

|

|

Classic detail of the XK engine

The oil-filler cap with incuse "JAGUAR" lettering cast in.

This beautiful detail was part of all XK engines from the XK-120 on through the Series 1 E-types, and somewhat beyond.

Subsequently, the cast caps were plain and did not carry the "JAGUAR" lettering.

|

|

|

|

|

|

Series 1 E-type roadster

This car needs some attention to details, but is overall reasonably presentable.

|

|

|

|

|

|

|

|

|

|

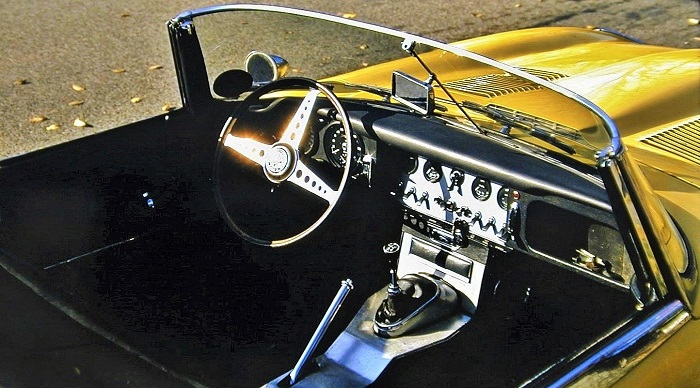

Series 1 2+2 dash

The late version of the toggle-switch central dash layout is seen here on a 2+2 coupe. By this stage of development the central dash trim material had been changed from the latter type of aluminum trim to the black trim.

The choke and choke warning light have been configured here to permit the fitting of the fluted chrome knob seen in the lower right of the picture. This knob controlled the direction of ventillation air in a continuous manner.

The earlier ventillation control system was comprised of a metal door with a small knob. A spring toggled the door to be either open or closed, but did not permit it to take an intermediate position.

|

|

|

|

|

|

Setting cam timing

This cam-timing tool was included in some E-type toolkits. It fit over the flanges near the front of the two camshafts and put them in the TDC position.

Here the tool is being used on the intake cam of a 3.8-liter E-type XK engine. The tang on the tool can be seen inserted in the notch machined in the flange on the cam. This positions the cam.

|

|

|

|

|

|

|

|

|

|

E-type carburation

Until the introduction of the Series 1.5 in 1968 all E-types had three SU HD8 carburetors, as seen here.

For markets outside U.S. these carburetors continued for a while, but finally dual Stromberg carburetors were used on all E-types, regardless of market.

|

|

|

|

|

|

Domed pistons in an XK engine

Various pistons, with different-height domes, set the compression ratio on the XK engine.

|

|

|

|

|

|

|

|

|

|

Fuel filter

This small wire-mesh basket filter was the final fuel filter before the gas entered the S.U. carburetors.

The spring pushed it out against the banjo fitting bringing fule into the float chamber.

Just another of the numerous beautiful small details of the E-type.

|

|

|

|

|

.jpg)