|

|

|

|

|

|

Aluminum crossflow radiators

The early E-types had aluminum crossflow radiators.

By the time of 4.2-liter production, the radiators were made of brass. Brass was the material of other post-war Jaguars up to 1961.

Not many of these original aluminum radiators are still in service. They are collector's items in their own right.

|

|

|

|

|

|

|

|

|

|

3.8-liter XK engine crankshaft

The 3.8-liter XK engine crankshafts had wider central main bearing journals than the subseuqent 4.2-liter engines.

This accomodated the closer cylinder spacings of the 4.2-liter engines.

|

|

|

|

|

|

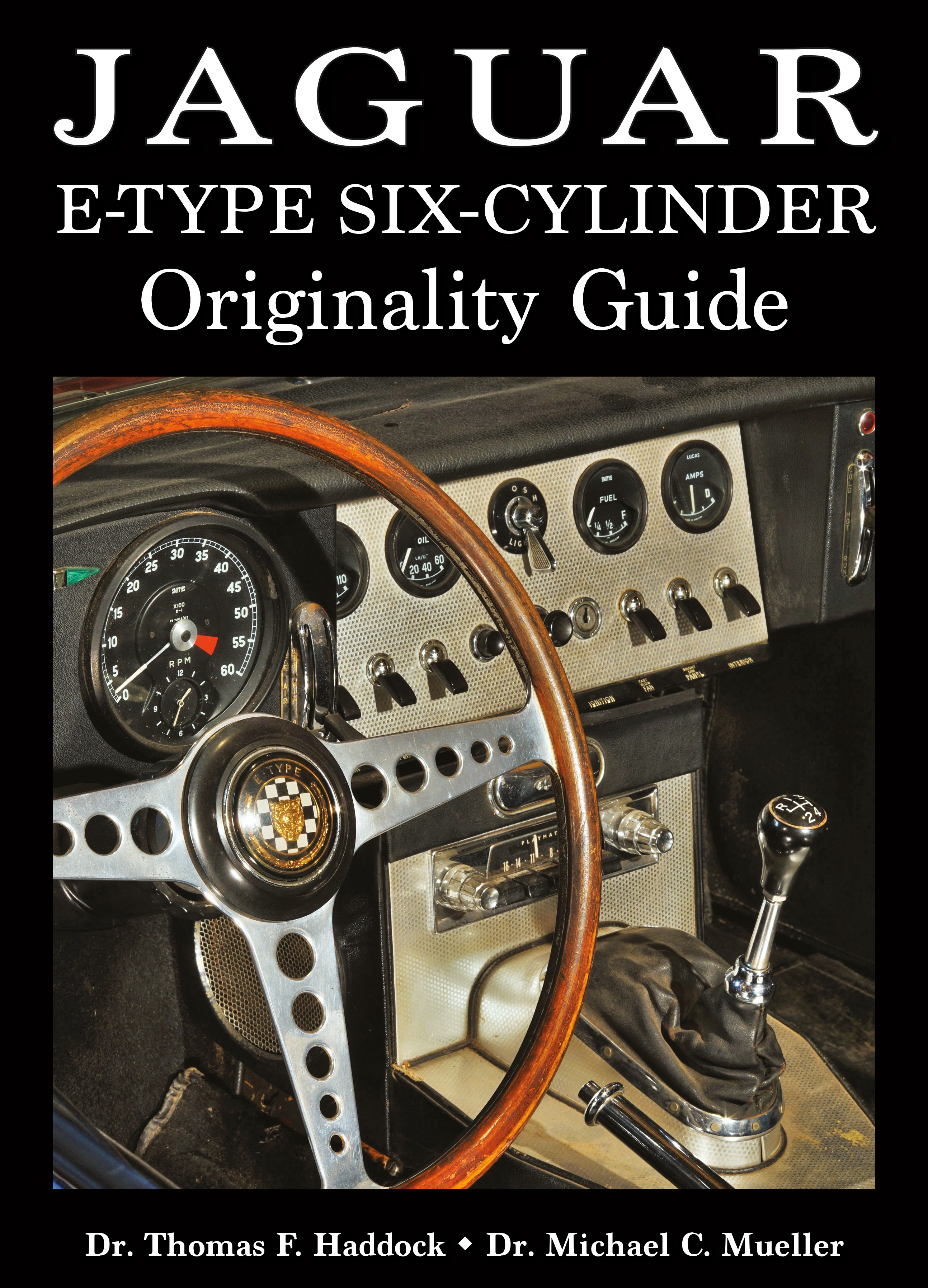

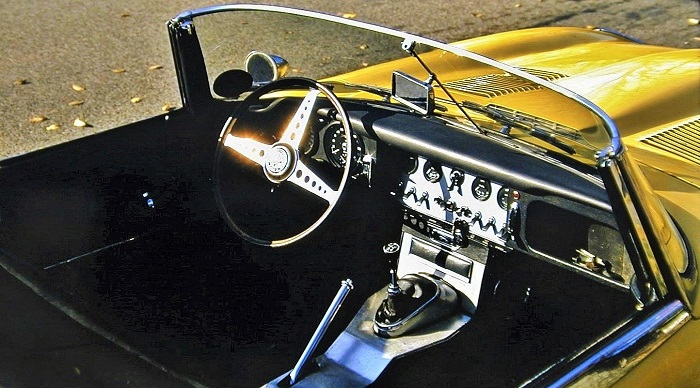

Another view of late-type 3.8-liter aluminum dash trim

The cross pattern aluminum trim on this later 3.8-liter car is in excellent condition.

It seems this cross-pattern aluminum finishing is not yet available as a reproduction. Reproductions of the earlier dot-pattern aluminum trim have been available for some time, although generally they do not accurately resemble the original.

The keys are not originals.

|

|

|

|

|

|

|

|

|

|

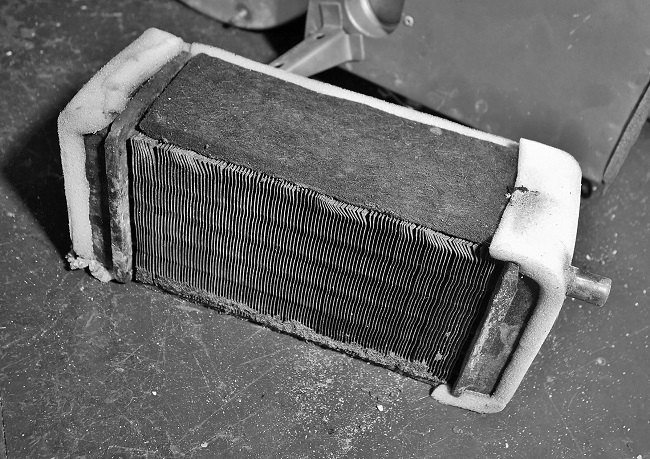

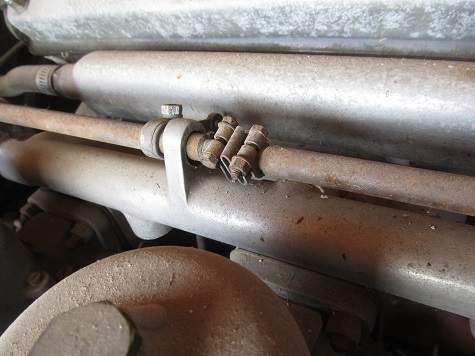

Heater core

The heater core is a small radiator housed in the heater housing bolted to the left front of the firewall.

While the 3.8-liter cars were fitted with aluminum radiators, these small cores were made of brass.

|

|

|

|

|

|

E-type Jaguar

An operable black E-type roadster.

|

|

|

|

|

|

|

|

|

|

Front belt pulley

The early pulleys were of the single-grooved type. Later on in 3.8-liter production a double-grooved pulley was used.

This one is aluminum; the later were made of steel.

|

|

|

|

|

|

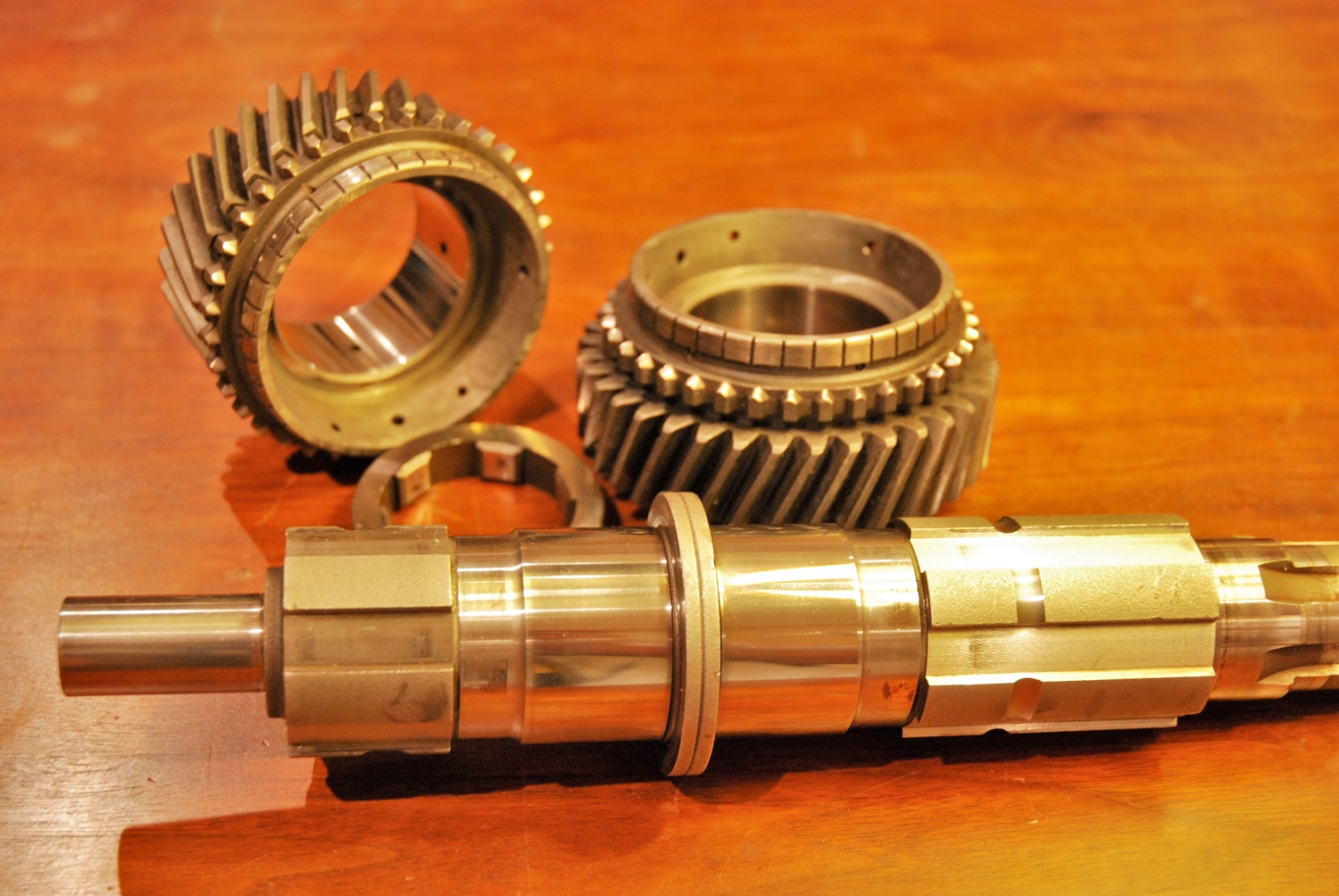

First and second gears of a Moss gearbox

The first and second gears show half the synchronizing cones.

While both these gears, as well as top gear, were technically synchronized, the system was not very effective, at least by modern standards. Double clutching for downshifts on these gearboxes is a good idea.

While these gearboxes used in 3.8-liter E-types are referred to as "Moss gearboxes," by this time they were actually made by Jaguar.

The new synchronizing system that came in with the 4.2-liter E-types used balk rings, and was much more effective. It also had forced lubrication.

|

|

|

|

|

|

|

|

|

|

XK engine cylinder head

The XK engine used a hemi head. This is the face side; the top had polished aluminum cam covers.

The face of this aluminum head has just been resurfaced.

|

|

|

|

|

|

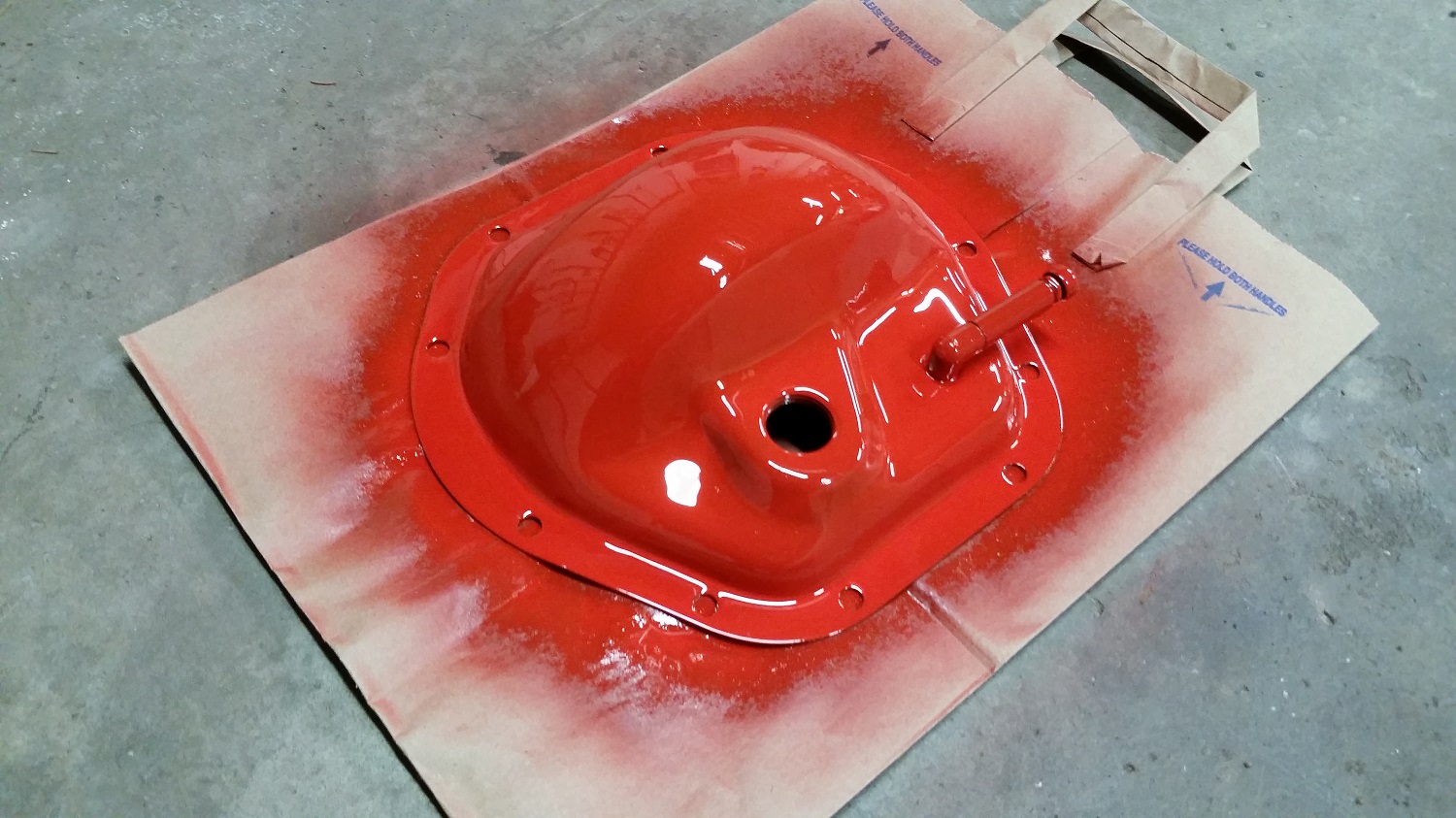

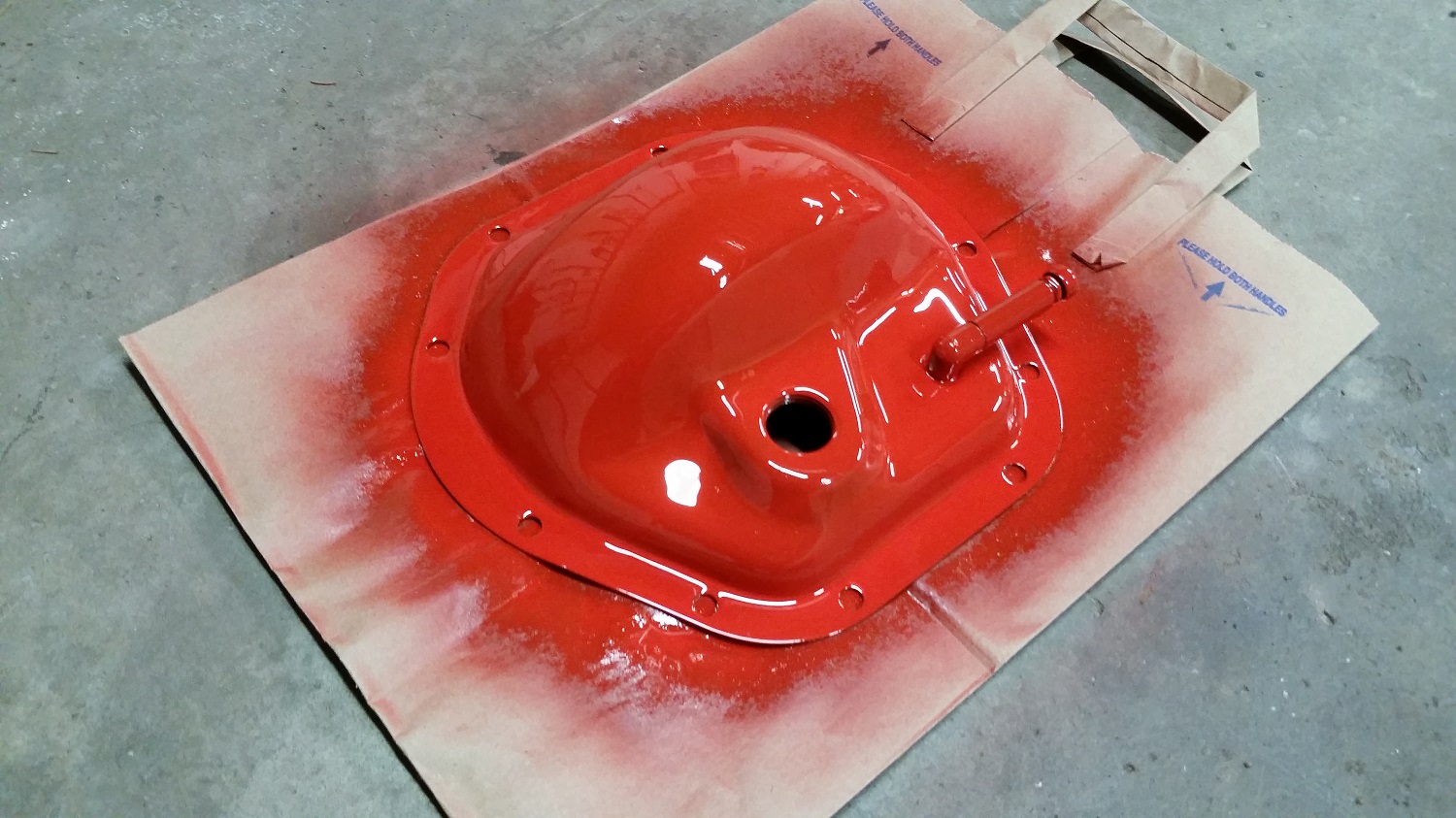

Differential cover

. . . repainted on a grocery bag.

|

|

|

|

|

|

|

|

|

|

Traditional XK-engine oil filler cap

From the 1940s to 1970s all XK engines were fitted with this lovely polished-aluminum oil-filler cap.

Later in XK-engine production the name "JAGUAR" was left off the cap.

|

|

|

|

|

|

Behind the glovebox

This view of an E-type is not usually seen. Often one of the last remaining areas of originality on an old car, this view shows the defroster hoses and some of the trim glue over the origanial white paint.

This area is usually preserved by all but a full restoration.

|

|

|

|

|

|

|

|

|

|

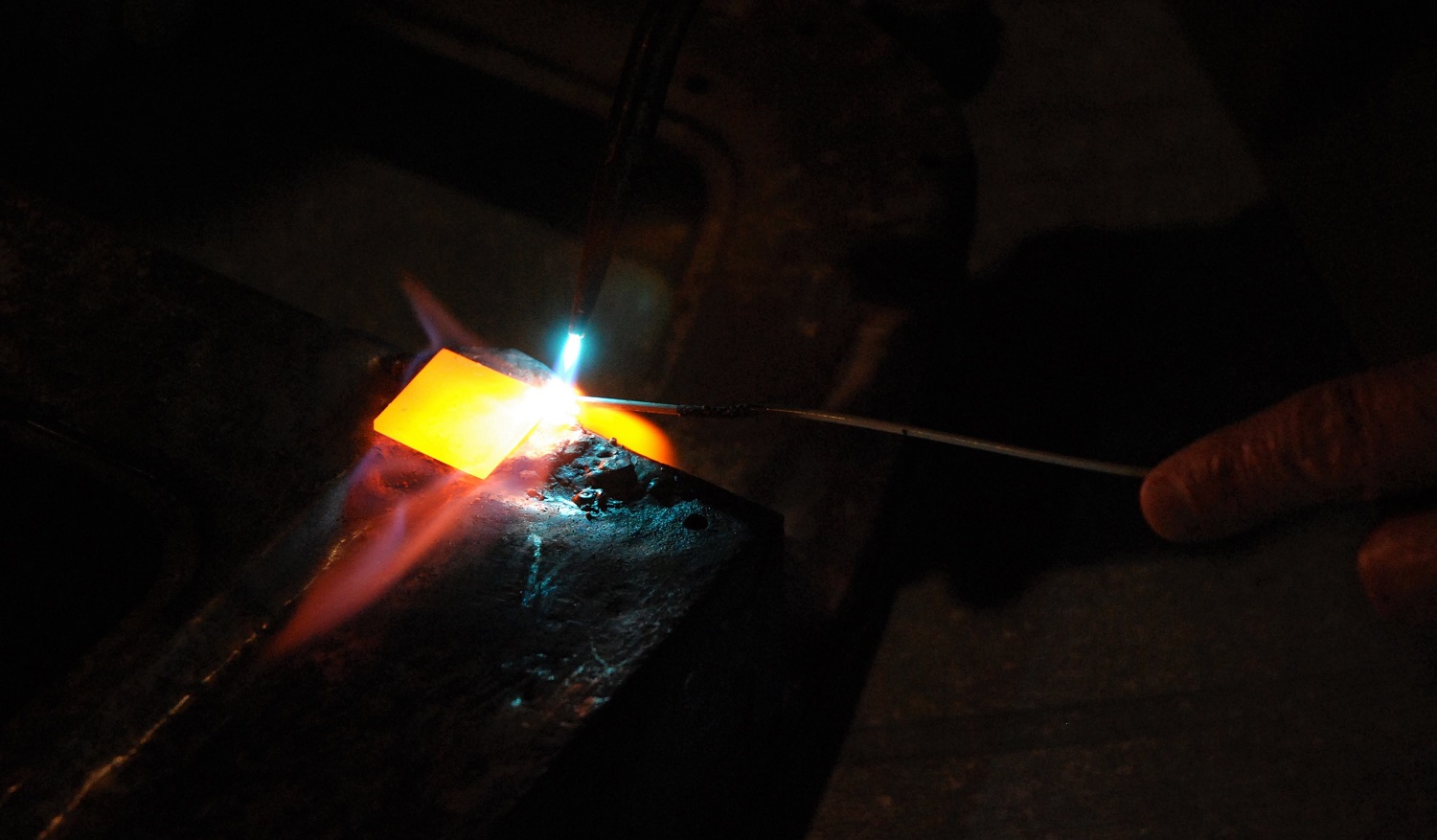

Rust repair

Here a rusted-out seat frame is getting welded up.

Almost any area of an E-type was subject to rust.

|

|

|

|

|

|

Early-style Series 1 steering wheel during rework

This rear-view of an early Series 1 (thick crossection) steering wheel during refinishing shows the irregular pattern of the thumb grooves.

Note that there are several sections where the thumb groove pattern is interrupted by an exceptionaly wide groove spacing.

On later wheels the thumb groove spacing was regular, at least between the spoke attachment points.

Bare unfinished wood is seen on this wheel.

|

|

|

|

|

|

|

|

|

|

Rear inboard brake caliper

Inboard rear disc brakes were one of the exceptionally-advanced technological features of the E-type.

Even today, this is still advanced technology.

|

|

|

|

|

|

Racing mirror on E-type roadster

Mirrors such as these were common in the 1950s and 1960s, and were found on many E-types.

It is likely more than half of the E-types in the U.S. were fitted with mirrors similar to this one.

|

|

|

|

|

|

|

|

|

|

Early E-type intake manifold and head

When the E-type was first introduced the spark-plug caps had this round-top CHAMPION design, the cylinder head paint was a pumpkin color, and the carburetor linkage was comprised of this rather complex arrangement of seperate levers.

The basic appearance, though was fundamentally unchanged from 1961 to 1967, with the polished aluminum componentry as used on all XK-engined Jaguars from 1948 onward.

In 1968, coincident with the implementation of the modifications to comply with the U.S. vehicle safety and emissions requirements, the prinicpal the main polished aluminum component, the cam covers, were changed to a finned design.

|

|

|

|

|

|

Limited-slip differential

View of the internals of the Series 1 E-type differntial.

|

|

|

|

|

|

|

|

|

|

Series 1 E-type roadster

. . . just rpior to driving.

|

|

|

|

|

|

Rear subframe emerging

The rear subframe of an E-type contains the rear drivetrain, brakes and suspension in a compact unit that comes out as a single piece.

The rear disc brakes are mounted inboard. The whole unit is a beautiful peice of engineering.

|

|

|

|

|

|

|

|

|

|

Moss gearbox housing

The housing of the Moss gearbox is made from cast-iron. These gearboxes are very durable.

There were variations in these castings during 3.8-liter XK-E production.

|

|

|

|

|

|

View down the bonnet

All features of the E-type bonnet are fully functional; there are no decorative embellishments.

|

|

|

|

|

|

|

|

|

|

E-type in the late 1960s or early 1970s

An old picture showing an E-type sitting in the sun.

|

|

|

|

|

|

Domed pistons in an XK engine

Various pistons, with different-height domes, set the compression ratio on the XK engine.

|

|

|

|

|

|

|

|

|

|

Fuel filter

This small wire-mesh basket filter was the final fuel filter before the gas entered the S.U. carburetors.

The spring pushed it out against the banjo fitting bringing fule into the float chamber.

Just another of the numerous beautiful small details of the E-type.

|

|

|

|

|

|

Night driving

"The Traveller Hasteth in the Evening."

|

|

|

|

|

|

|

|

|

|

Middle level vent

Here the flaring at the edges of the vent trim had been introduced, but was later to be increased.

|

|

|

|

|

|

Barn find series number four

Chains attached to the rear lower suspension members allow the car to be pulled out of storage and onto the awaiting flatbed.

|

|

|

|

|

|

|

|

|

|

Barn find series number three

The car finally emerges.

It will not start, but will be transported on a flatbed.

|

|

|

|

|

|

Barn find series number two

Both human and animal tracks are traced out on the windshield.

|

|

|

|

|

|

|

|

|

|

Barn find series number one

After decades of storage this E-type prepres to emerge into the light.

Rocking and pushing gets the car to again roll, but with much resistance.

|

|

|

|

|

|

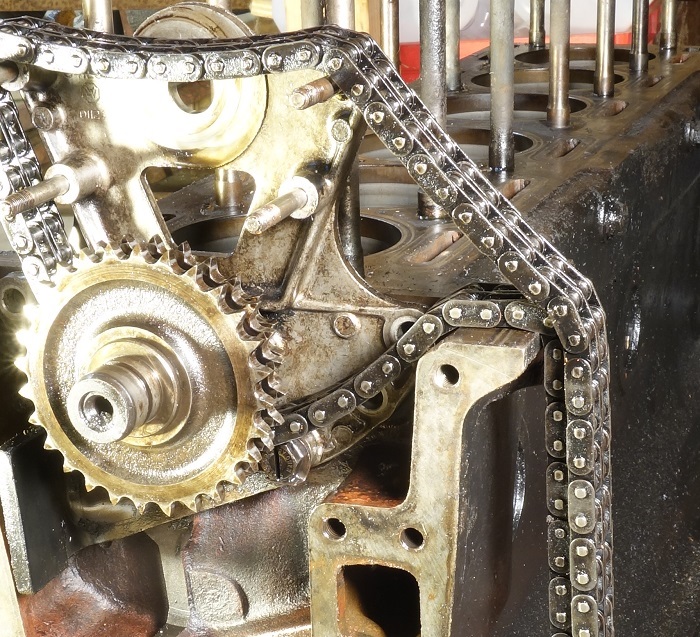

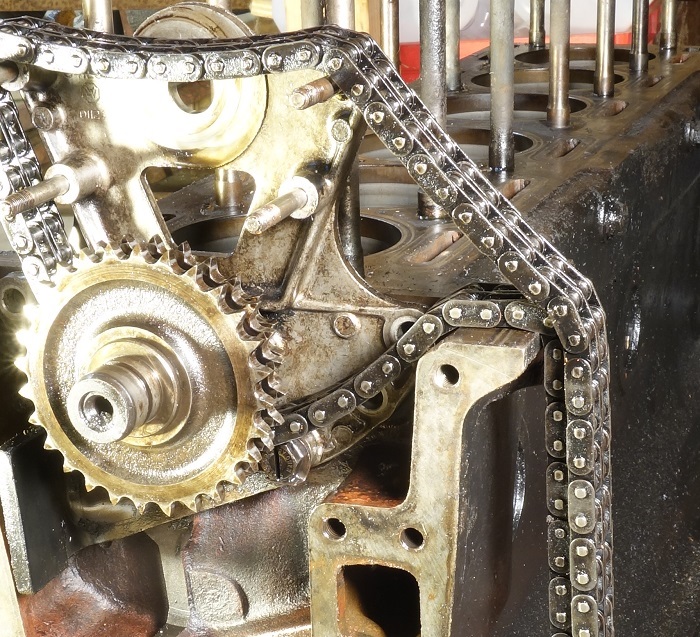

Timing chain transition

This part is the intermediate timing chain sprocket. Here the upper timing chain is wrapping round the smaller part of sprocket; the larger part is not showing here, but it is driven by the lower timing chain.

The effect of this is that the ratio between the cam rotation rate and the crank rotation rate is not set only by the relative sizes of the crank sprocked and the cam sprockets, but by this intermediate sprocket with two different radii.

|

|

|

|

|

|

|

|

|

|

The wood-rimmed drilled aluminum steering wheel

This is an alternate, back, view of the E-type steering wheel. From here the attachment of the planar aluminum wheel to the hub can be seen.

Aluminum rivets are used to attach the steering wheel to the hub, but in restorations often screws are used.

The steering wheel, like essentially all parts of the car, is beautiful when seen from any angle, not just the usual front view.

|

|

|

|

|

|

Radiator comparison

This side-by-side comparison between an original Marston Excelcisor radiator (top) and a popular reproduction (bottom).

The reproduction radiator has a reproduction serial-number plate. The crimped ends of the horizontal sections of the original radiator are simulated in the reproduction by machined-in flutes. Once painted, these reproductions are reasonably close in appearance to the originals.

Also of note here, the number plate is located off-center. This is often found on original radiators, and the same location has been selected for reproduction plate.

|

|

|

|

|

|

|

|

|

|

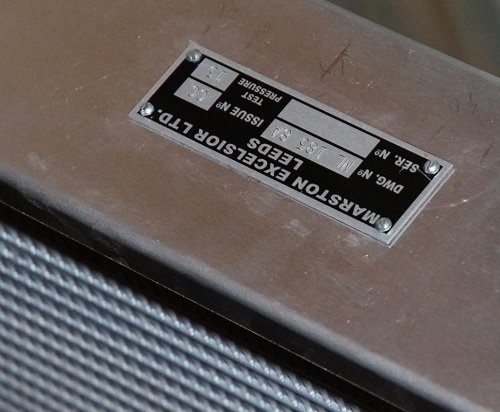

Closer view of reproduction radiator serial number plate

This view of the reproduction radiator nubmer plate shows four retention screws that are very close to the small domed originals.

Such screws, of the right size and form, can be very hard to find, and very often incorrect replacments are used.

The characters on this number place are those that were present when it arrived from the supplier. The serial number frame is left empty, since the original radiator on this particular car was missing, and thus the original serial number was not known.

|

|

|

|

|

|

Early-Style 3.8-liter Throttle Linakge

This early-type throttle linkage was comprised of many more components than the later type, including the corrigated coupling spring used to join two of the components.

While the 3.4- and 3.8-liter XK-150S cars used the multi-piece linkage, it differed from that of the early E-type linkages.

|

|

|

|

|

|

|

|

|

|

XK "S" Type Engine In Another Guise

The XK "S" type engine was used in the XK-150S, as well as in the Mk X sedan.

Here is an "S" type engine from a Mk X. The oil filter is vertical instead of horizontal, the engine mounts are different, as is the sump. Note that the cooling fan here is driven off the water-pump drive, in contrast to the electrical cooling fan used in the E-type (one of the first, if not the first, such cooling-fan configurations).

Also note the overdrive unit on the rear of the Moss gearbox. This feature was never offered on E-types. Space was at least one of the considerations.

|

|

|

|

|

|

Later-Type 3.8-liter Dash Aluminum Patterning

After the raised polka-dot aluminum pattering this incuse-cross type was introduced.

It ran until the black patterned vynal covering was introduced late in 3.8-liter production. The dark covering then ran for the rest of E-type production. type.

|

|

|

|

|

|

|

|

|

|

Bent connecting rod

A bent connecting rod.

Possibly the result of hydrolock.

|

|

|

|

|

|

One-Piece Intermediate Pulley

Early E-types had two-piece intermediate pulleys, in the style of the previous XK-series cars.

The change to the one-piece unit, shown here, occurred early in 3.8-liter E-type production.

|

|

|

|

|

|

|

|

|

|

Modified Series 1 Coupe

A coupe heavily modified for racing.

|

|

|

|

|

|

Blown-up 3.8-liter engine

Rear piston protruding from the left-side of the block.

The result of over-revving.

|

|

|

|

|

|

|

|

|

|

View of Trunk Lid

the 3.8-liter cars did not have the "E-TYPE" label that the 4.2-liter cars had, nor was their displacement shown.

|

|

|

|

|

|

Series 1 Bonnet

The bonnet tipping forward for engine access was remarkable when the E-type was introduced in 1961.

However, the E-type was not the first car with this type of bonnet. For example, the Aston Martin DB2 used this arrangment during its production from 1950 to 1953.

|

|

|

|

|

|

|

|

|

|

Engine Teardown

A 4.2-liter Series 1 coupe with engine out and head off for repair.

|

|

|

|

|

|

3.8-liter XK Crankshaft

The counterweighted crankshaft of the XK engine rode on seven main bearings.

In the lower part of this illustration the central main bearing is shown. On eitehr side of the main journal are the two thrust bearing surfaces. All the thrust load was takin on these two surfaces.

|

|

|

|

|

|

|

|

|

|

Cracked engine block

This 4.2-liter block was frozen by a lack of antifreeze. While the core plugs might have releved some of the freezing stress, they cannot be counted on to releave it all. In this case the result was a crack running down the block.

The crack was welded, but with undetermined results.

|

|

|

|

|

|

Close-up of a restored early 3.8-liter XK cylinder head valley

This close-up shows the pumpkin-colored paint of the early cars. Later engines had a metallic gold paint, although both are referred to as "gold-top" engines, or XK "S-type" engines.

The early style of spark-plug cap is shown here, with "Champion" written in a circular manner around a small raised boss in the center.

There were several styles of spark-plug caps used throughout the XK-engine run.

|

|

|

|

|

|

|

|

|

|

1963 coupe at the bottom of the market

In the early 1970s E-types were relatively common used cars. While they have always been exceptionally beautiful mechanical objects, at the time this was generally unrecoginzed.

While it seems remarkable now, The owner of this car spent money to place a newspaper advertisement offering the car free just to get rid of it, with text of "Tow it away and its yours."

Apparently the car was not running due to a minor cooling-system problem. While this might have what kept it from running, there were likely many other problems.

The exhaust system is from a Series 2 car, as can be seen by the splayed-out resonator pipes.

|

|

|

|

|

|

Collection of Jag parts

XK engines and other drivetrain parts in various states of disassemlby.

|

|

|

|

|

|

|

|

|

|

Fuel level sender unit

Years of deposits from gasoline coating the sender and evaporating almost obscure the unit entirely. The pivot rod was frozen in place, registering a fixed fuel quantity regardless of the level in the tank.

|

|

|

|

|

|

XK Engine Awaiting Restoration

An engine in such rough-appearing condition would be a satisifying restoration project.

This one appears to have been stored outside for some time.

|

|

|

|

|

|

|

|

|

|

Cantilevered Space-Frame Attachment Point

The front frame section is built up to three main components, with the rearmost two bolted to the firewall. An attachment point is shown here.

Bolting the frame on the tub in this manner made for easy replacement of damaged frame members. The D-types originally had welded-on frame members. The bolts used here are not original.

|

|

|

|

|