|

|

|

|

|

|

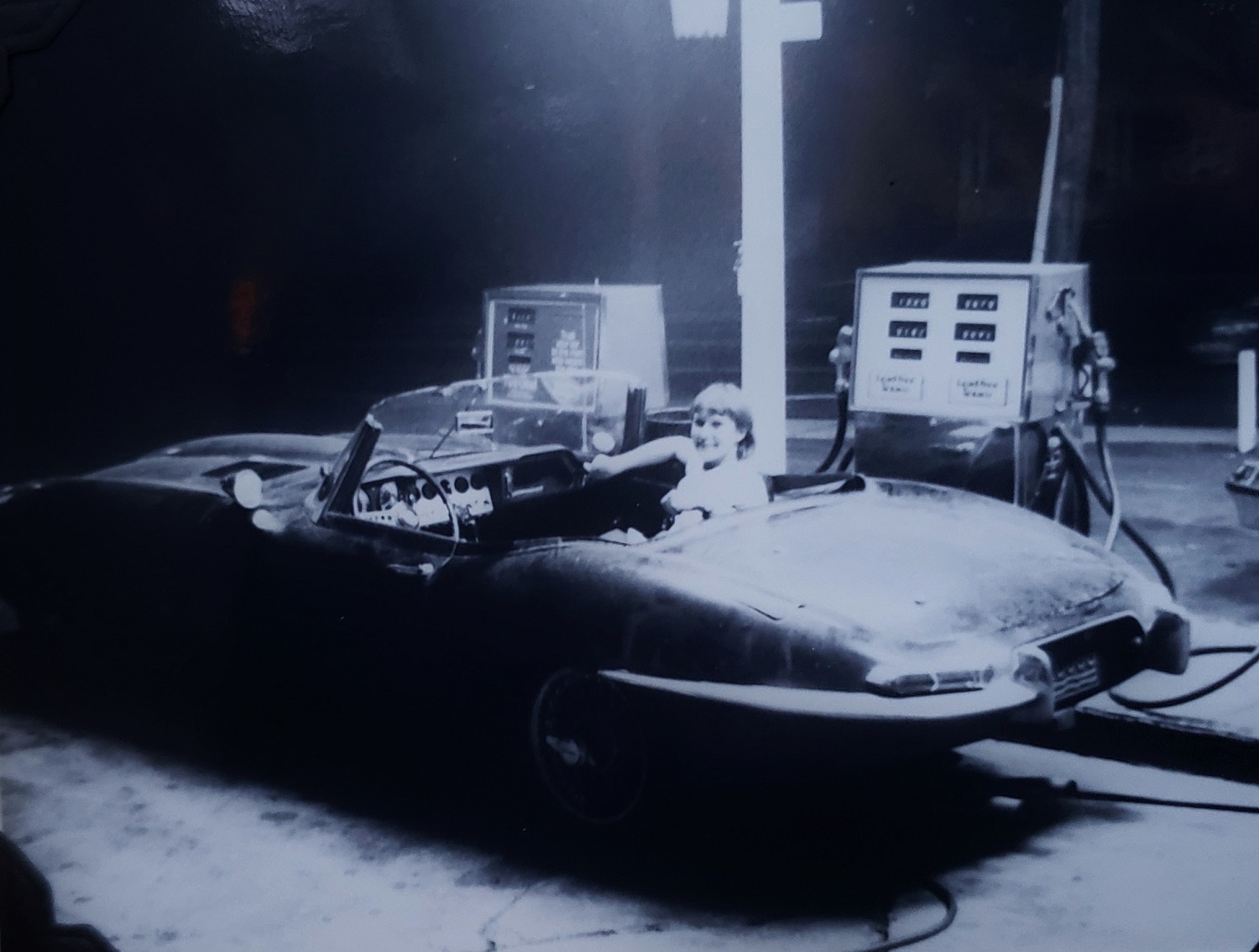

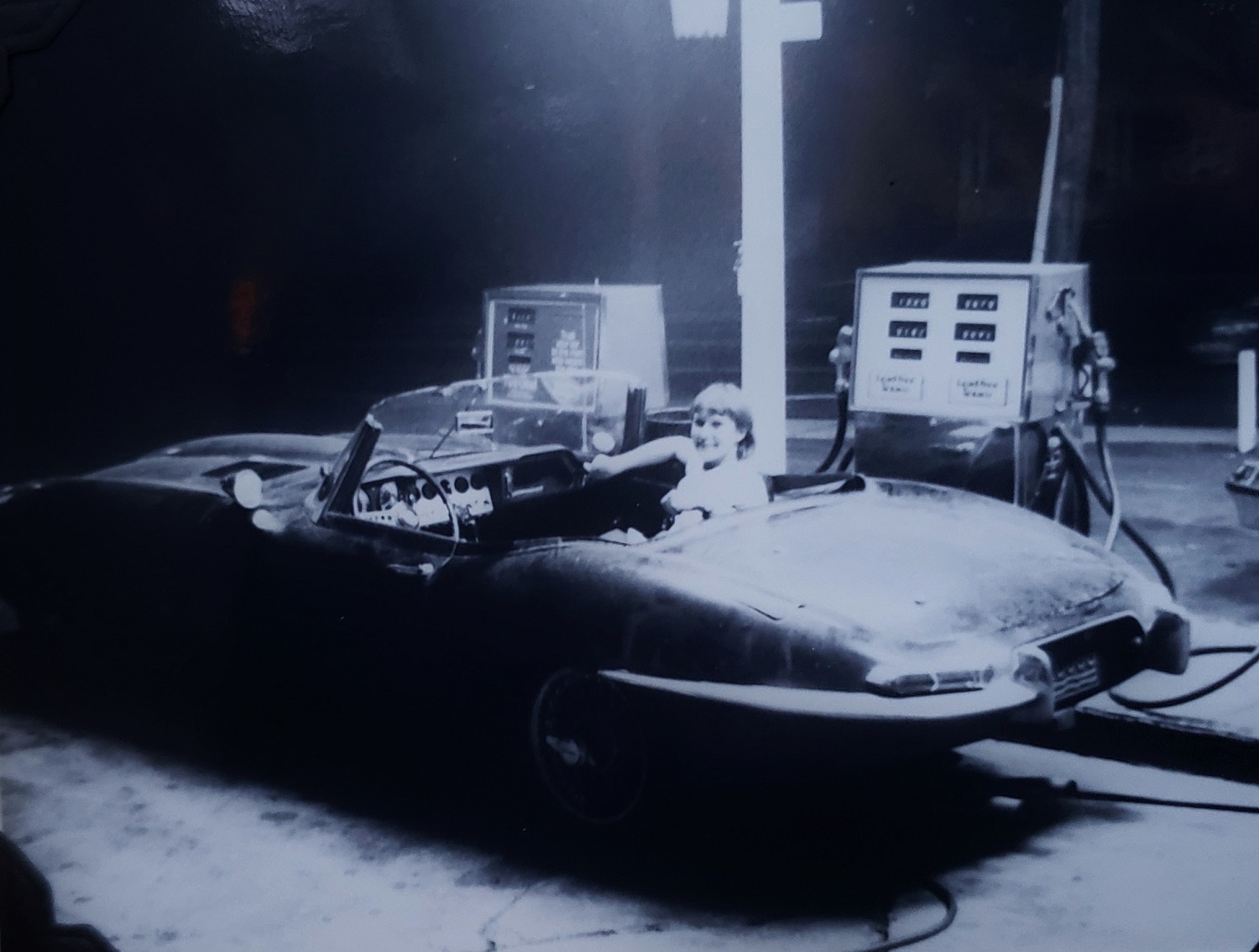

Night fuel stop

E-type on a road trip in the 1970s.

Sitting in a gas station off a country two-lane.

|

|

|

|

|

|

|

|

|

|

E-type roadster parked on a lawn

|

|

|

|

|

|

Night driving in a 4.2-liter E-type coupe

|

|

.jpg)

|

|

|

|

|

|

|

|

Early-style fuel tank sump

The early sumps were made up of individual pieces that screwed together, while later designs were of a fabricated single-peice design.

Here the brass bottom piece and be clearly seen. It can screw off from the main body.

|

|

|

|

|

|

Plastigaugeing an XK engine crankshaft

Checking clearances during a rebuild.

|

|

|

|

|

|

|

|

|

|

Shelley jack

|

|

|

|

|

|

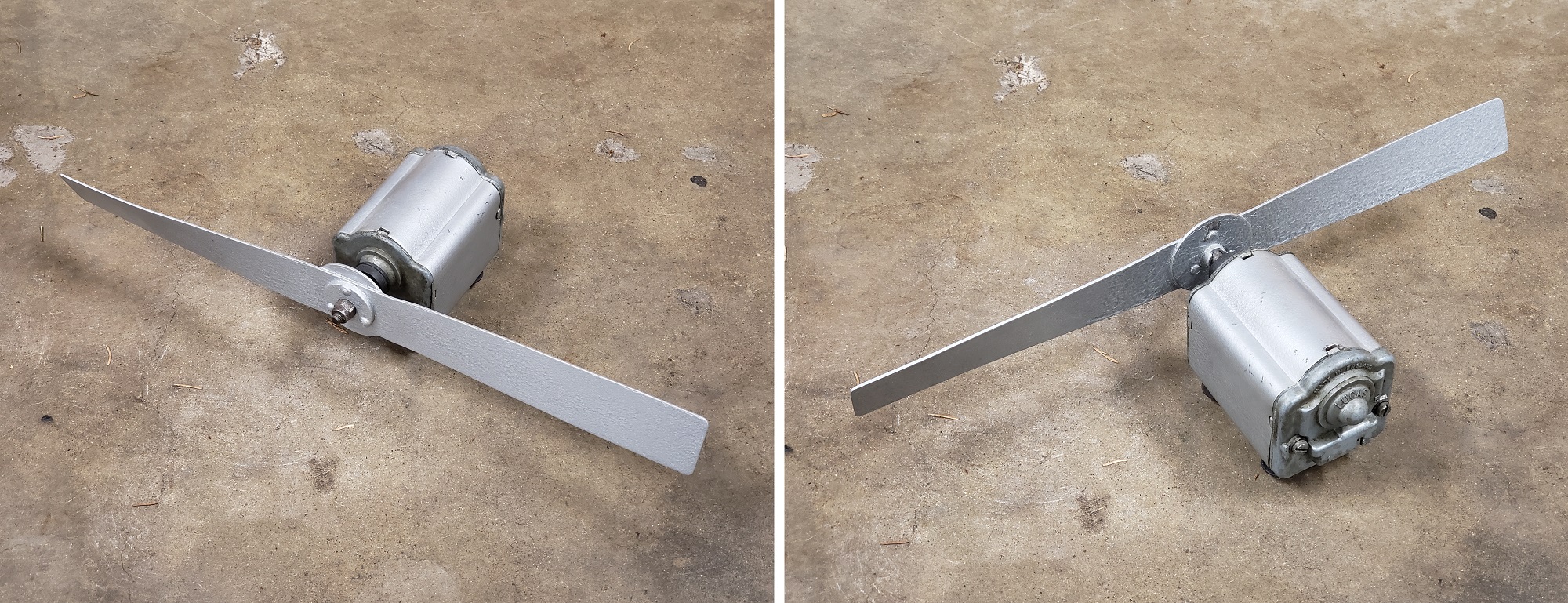

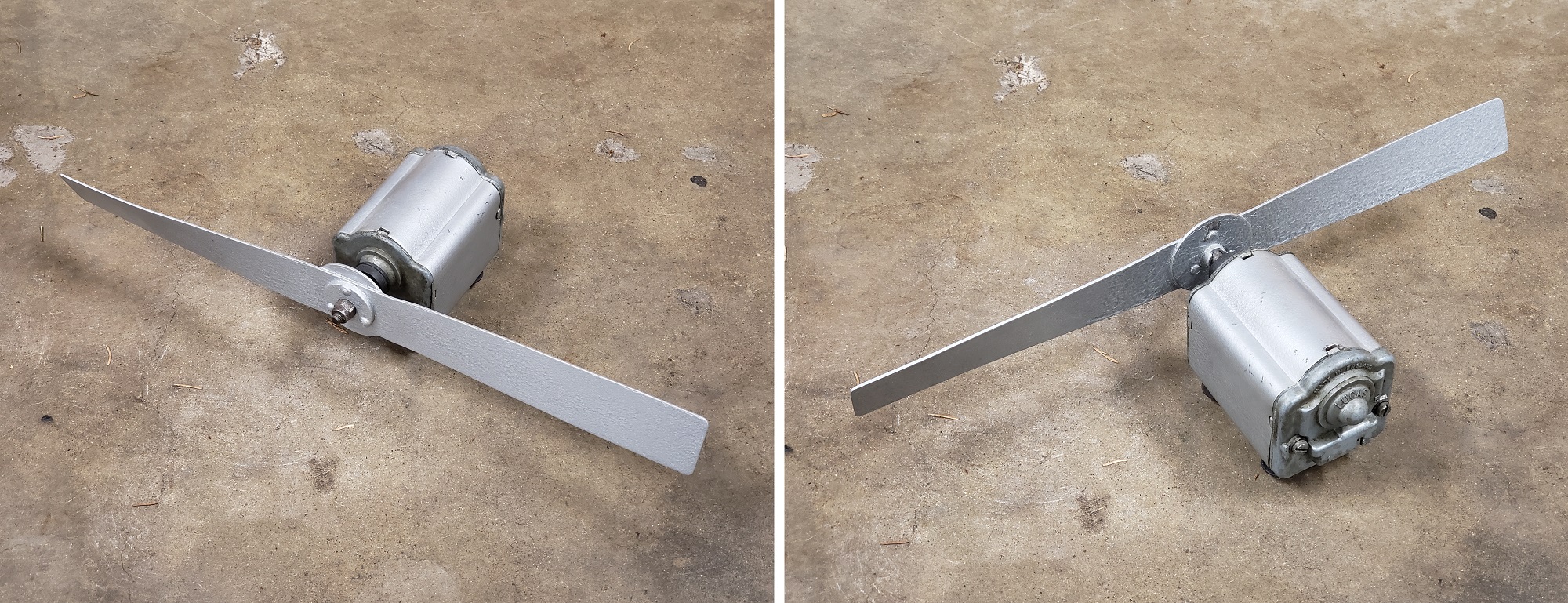

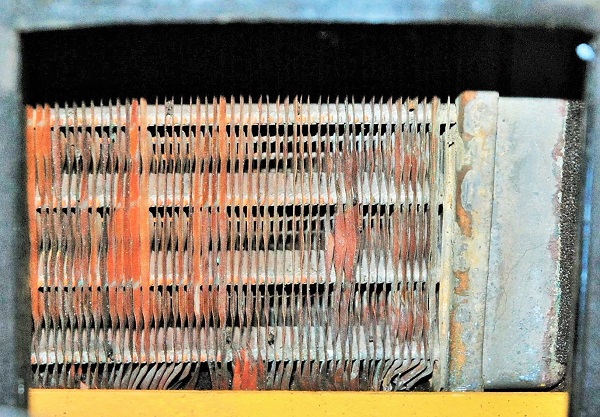

Electrically-driven engine-cooling fan

The forced airflow for engine cooling was driven by this electric fan, seen in two views here. This was one of the first, and possibly even the first, example of an electric fan used to drive air through the radiator.

The motor is similar to those used for some time previously to drive the windshield-wiper systems on various British cars, including Jaguars.

This early design is very different from the plastic cooling fans used today.

|

|

|

|

|

|

|

|

|

|

Steering wheel collets

This set of two collets were used to locate the steering wheel on its shaft.

|

|

|

|

|

|

Checking the oil during a fuel stop

This exposed side-view makes clear the demarcation from the front and rear structures of the car - the space frame cantilevered off the firewall on the front, and the monocoque rear tub comprising the rear section.

Though the E-type was introduced over five decades ago, checking the oil during fueling is still a dramatic scene today.

|

|

|

|

|

|

|

|

|

|

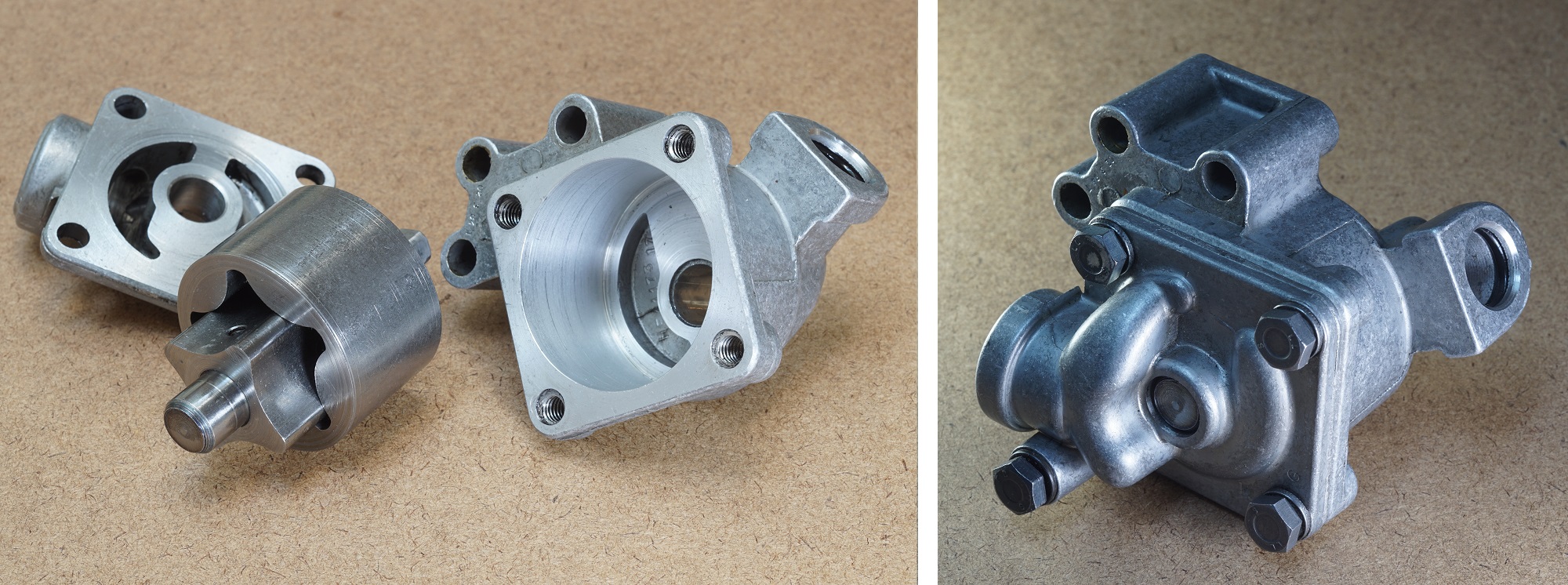

XK-engine Oil Pump

This pump is from the era of the E-type; different styles of pumps were used during the long production period of the XK-engine.

On the left the pump is seen dissembled, while the assembled unit is seen on the right.

Some earlier XK engines used gear-type pumps.

|

|

|

|

|

|

Shift knob on Moss gearbox

This original 3.8-liter type shift knob is on a Moss gearbox in storage. The shift lever is the very short type used on E-types.

The non-original lock-nut below the shift knob is thicker axially than the very-thin original type.

This beautiful knob, with the pattern on the inside of a clear dome on the top, was the earliest type used on E-type Jaguars.

|

|

|

|

|

|

|

|

|

|

Counterbalance spring mechanism.

This unit is broken, as often happened. It has already had an earlier repair, seen in the bright-plated dome-headed bolt on the far right.

This design was replaced during Series 2 production with a gas-filled cylinder.

|

|

|

|

|

|

Amco walnut shift knob

These shift knobs were a popular aftermarket accessory for sports cars in the U.S. market in the 1960s and 1970s. They were also offered with chromed metal instead of wood.

This one has an enamel Jaguar emblem on it. The style is similar to the E-type horn button design, but with

the legend "JAGUAR" across the top instead of the "E-TYPE" legend used on the horn button.

Amco knobs were available from accesory catalogs issued by vendors such as Vilem B. Haan and MG Mitten, who also ran advertisements in sports car magazines such as Road & Track and Car and Driver.

Modifications carried out on a car in-period, such as this shift knob and the aftermarkt key fob seen in the background, raise questions about the balance between strict originality and preserving history.

|

|

|

|

|

|

|

|

|

|

Horn relay

This relay has its cover removed. It is stamped "11 62," indicating a Noveber 1962 manufacture date.

Opened up, the coil can be seen, with the high-current contact seen on the right.

On modern cars relays are generally located in a central location, usually along with the fuses. On E-types, and most cars of their period, relays were located at various places on the chassis, typically not too far from the components they actuated.

|

|

|

|

|

|

Needle bearings from Moss transmission

There are many needle bearings in the Moss transmission used in the 3.8-liter E-types.

Springs, such as seen here, operated detents acting on the shifting rings (with internal dog teeth) and synchronizer cones (with external dog teeth).

|

|

|

|

|

|

|

|

|

|

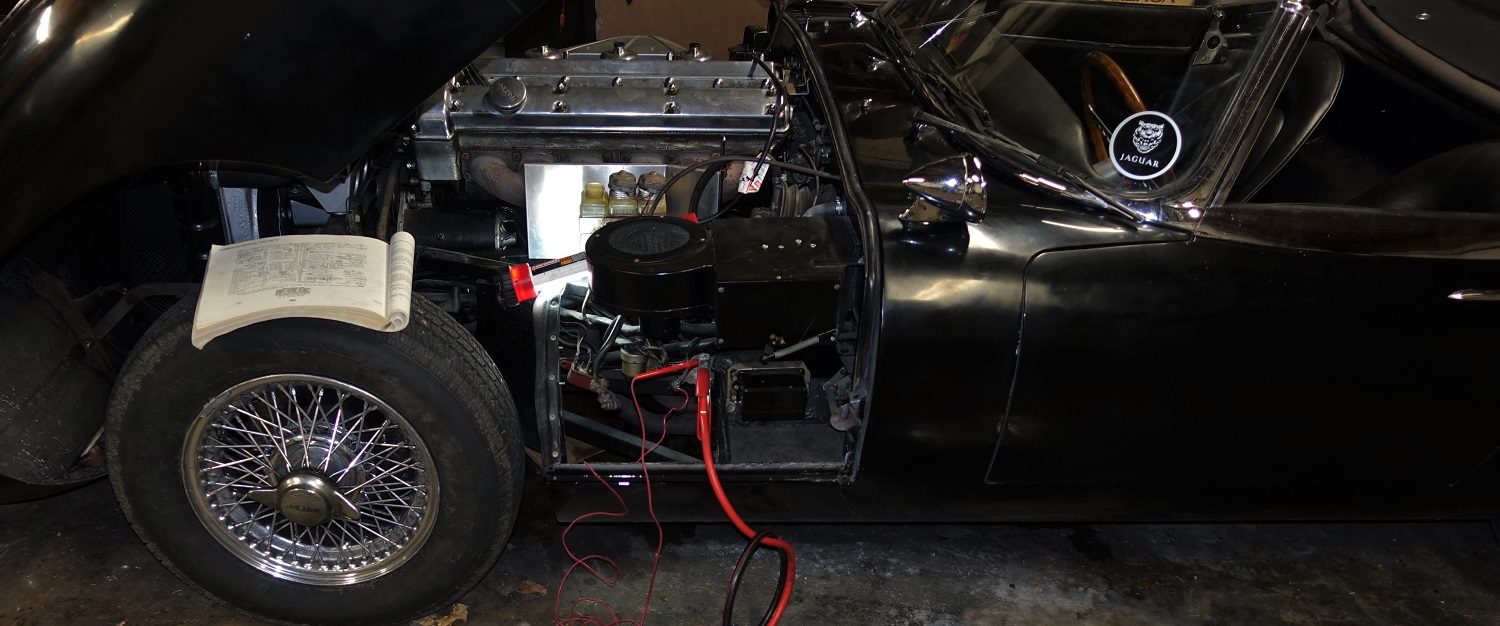

E-type undergoing electrical repairs

Electrical repairs are being made with the Bentley manual, turned to the wiring diagram, sitting on the drivers-side wheel.

|

|

|

|

|

|

The XK Engine

View of a gold-top 3.8-liter E-Type engine.

This nice-looking engine compartment shows the multi-piece manifold typical of the 3.8-liter cars. The 4.2 liter cars had a much simplified manifold.

An aftermarket radiator is fitted. As is almost always the case, non-original tires have been installed.

|

|

|

|

|

|

|

|

|

|

Concourse in the rain

Rain at a Jaguar Associates Group of Michigan (JAGM) concourse did not discourage many entrants. This wet Series 2 4.2 liter E-Type is awaiting judging.

From this view, the notably-raised headlight positions of the Series 2 cars are evident.

The headlight assembly modifications from Series 1 to Series 2 took place in two stages. First, the Series 1.5 cars (and some very late Series 1 cars, sometimes referred to as Series 1.25) were fitted with un-covered lights (not mounted as high the Series 2 cars). Then the Series 2 cars had the very high location as seen here.

|

|

|

|

|

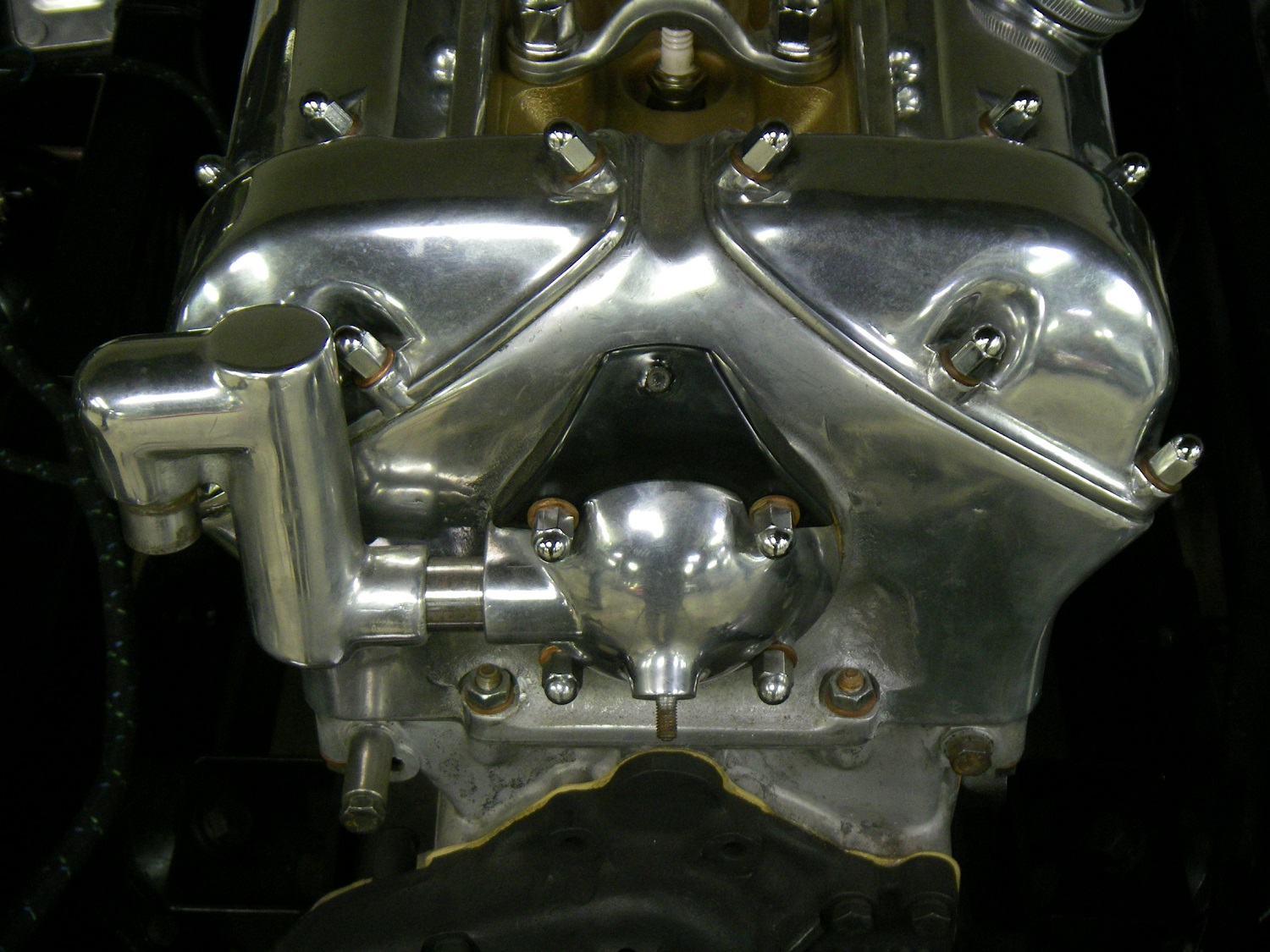

Front of the XK cylinder head

The polishing of the head, and many other aluminum components, in an E-Type connects it to long-standing British tradition.

The aluminum castings can almost always be polished and re-polished to restore their factory finish.

|

|

|

|

|

|

|

|

|

|

A rare Dunlop RS5 tire

When the E-Type was first introduced in 1961 it was fitted at the factory with these Dunlop crossply tires. Not many are still around.

This one, a spare, shows only light checking, probably due to its being away from the light in the spare tire well. While the rubber is too old to permit driving on them, their presence contributes to the accuracy of a car.

|

|

|

|

|

Made in China

As time has passed more and more replacement parts are non-NOS and not original used parts. This freeze plug states its origin in large capital letters in its direct center.

This is an example of the trade offs between the parts originally supplied with the car, that may be no longer servicable, NOS factory replacement parts that typically make an accurate replacement, and third-part parts that may deviate from the original character.

|

|

|

|

|

|

|

|

|

|

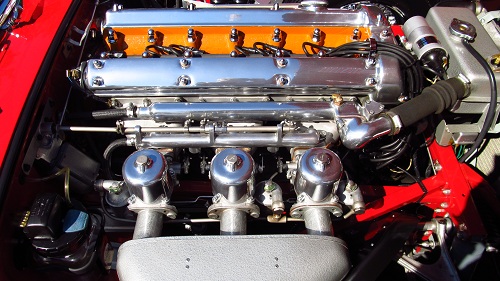

Side view of a 3.8 liter E-Type engine

This nicely restored engine compartment shows the replacement "pumpkin colored" cylinder head paint of the early 3.8-liter cars.

|

|

|

|

|

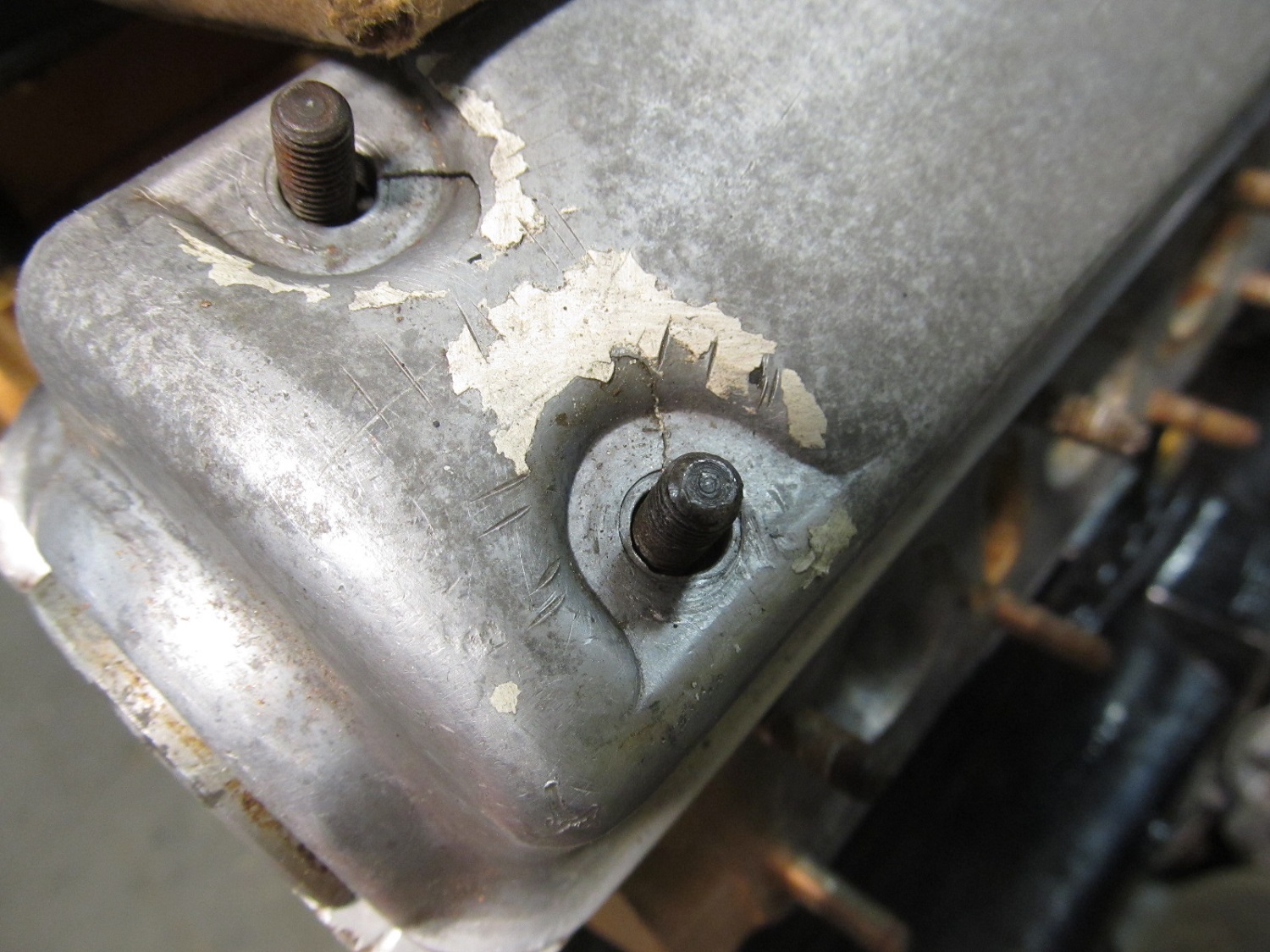

Frequent problem with cam covers

The aluminum cam covers were delicate and very susceptible to cracking under over-tightening of the chrome domed cam cover nuts.

This cam cover from a 4.2-liter XK engine has been cracked by over tightening, and it appears some caulk or body-putty has been used in the past to stop oil leaking.

|

|

|

|

|

|

|

|

|

|

View down an intake port

The back of an intake valve and the end of an intake valve giude can be seen in this cleaned up and ready to go in this intake port of a 4.2-liter engine.

|

|

|

|

|

Early US-spec Series 2 engine

This highly-polished Series 2 engine still adheres quite closely to factory specificaitons. The crossover pipe at the rear of the engine (the left-hand side) carries intake air to the exhaust manifold for pre-heating to reduce emissions.

|

|

|

|

|

|

|

|

|

|

Dark blue Series 3 V12 roadster with hardtop

The Series 3 cars brought the 9"-longer chassis of the six-cylinder 2+2 to the roadster as well.

Note the windshield-washer dual-spray nozzle is mounted on the hood bulge as the windshield on these later long-wheelbase cars was brought forward to where the nozzles were situated at first (there were two single-spray nozzles).

|

|

|

|

|

Collection of E-Type wheels

A group of E-Type 15-inch wire wheels. Some are the early type, while a few are of the later Series 2 type. One of these can be seen at the very back.

|

|

|

|

|

|

|

|

|

|

3.8-liter E-Type shift knob

The 3.8-liter E-types were fitted with a pear-shaped black plastic shift knob with a clear plastic dome with the shift pattern inside it.

These knobs were a break with the earlier Jaguar shift knobs, and in fact generally with other British shift knobs of the time, which were black polymer moldings with the shift pattern molded in an incuse manner on the top. These shiftknobs are one of the many appealing details of the early E-Types.

Possibly some similar clear-top knobs came out on the Mk 2 sedan prior to the introduction of the E-type.

|

|

|

|

|

Parts in storage

Series I E-Type parts in long-term storage.

|

|

|

|

|

|

|

|

|

|

View of the rearend of a Series 1 roadster

The lights and bumpers of the Series 1 cars were very succinct.

Later, these were altered and the lights enlarged for the Series 2 cars.

|

|

|

|

|

Fiftieth Year Anneversary event put on by Jaguar

The entrance to the Fiftieth Year E-Type Anneversary event on the Monterey peninsula.

On the left is prototype E1A, in the middle is the Geneva Show coupe, and on the right is the New York Show coupe.

|

|

|

|

|

|

|

|

|

|

Original retaining wires

This end view of an intake camshaft galley shows the factory-installed lock wires for the sprocket-retaining bolts.

This is the type of small detail that often gets lost even during very accurate and careful restorations. Preservation of very original cars keeps these technical details from being lost. There is value in preserving very original cars even if their condiciton is not perfect.

|

|

|

|

|

Mistreated Moss gearbox

One of the aspects of driving a 3.8-liter is the Moss gearbox. This design, dating back to the 1930s has a non-synchromesh first gear (and of course reverse as well), with straight-cut spur gears. There is no synchromesh sleeve to align dogs to a collar; the gear teeth themselves must be engaged to engage first or reverse.

Engagement of first gear requires either stopping the car, or skillful double clutching, but many Moss gearboxes were damaged through improper operation. Here a badly-damaged first/reverse cluster on the layshaft from a 1963 E-Type roadster gearbox.

The synchromesh on the other three gears, second, third and fourth, is generally marginal in performance. Double clutching into second and third is often needed as well.

|

|

|

|

|

|

|

|

|

|

Lucas PL headlight

Tri-bar Cassegrain-reflector-type Lucas PL headlights were factory equipment for early E-Types for certain markets.

This is an original light shown. Aftermarket replacements are available now in a range of qualities.

|

|

|

|

|

Size comparison

Parked among a random selection of modern cars, the small size of the E-Type roadster is apprent.

|

|

|

|

|

|

|

|

|

|

Painted wire wheel from a 1961 E-Type

This wheel, from a first-year US-specificaiton car, is painted instead of chromed.

The rubber skirt, protecting the inner tube from the spoke nipples, has hardened and broken.

|

|

|

|

|

Third and second gears

The third and second gears from a Moss gearbox from a 3.8-liter E-Type are helical gears, in contrast to the straight-cut spur gears of first and reverse.

Fourth gear is not actually a gear, but the straight through connection from the input shaft to the output shaft using the dogs on the third gear and the third-gear/fourth-gear dog collar.

|

|

|

|

|

|

|

|

|

|

The dot-pattern aluminum trim

The center consol of this 3.8-liter E-Type shows the early type polka-dot pattern.

Other trim types were later used, including incuse cross-pattern markings and finally upholestered (as used in Series-1 4.2-liter cars).

|

|

|

|

|

Regulation bumpers

This 5.3-liter Series-3 V-12 E-Type has the large rubber bumpers designed to meet US-crash specs.

This V-12 car also has chrome pressed-steel wheels. Before the Series-2 cars, all production E-Types were fitted with wire wheels; later wire and pressed steel wheels were offered.

|

|

|

|

|

|

|

|

|

|

4.2-liter Series-1 roadster

This car, now referred to as a "Series-1" was only so named after the later Series-2 cars were introduced.

|

|

|

|

|

|

Removing exhaust headers.

A somewhat common occurrence when removing downpipes from exhaust manifolds is breaking one of the four studs.

In this instance, the breakage occurred in spite of the brass nuts used when the system was assembled years ago.

|

|

|

|

|

|

|

|

|

|

Right rear light and bumper of a Series 1 4.2-liter coupe.

View of a generally nicely-restored Series 1 coupe.

|

|

|

|

|

|

Early style throttle linkage on a 3.8-liter engine.

A beautiful example of the mulit-piece throttle linkage system as used on the first E-types. A similar system was used on XK-150 cars.

The later linkages were signigicantly simplified.

The dash-pot dampener tops are brass, as they should be for this early car (these were changes to black plastic around 1963). In addition, in this case they are properly plated showing a matte silver color.

|

|

|

|

|

|

|

|

|

|

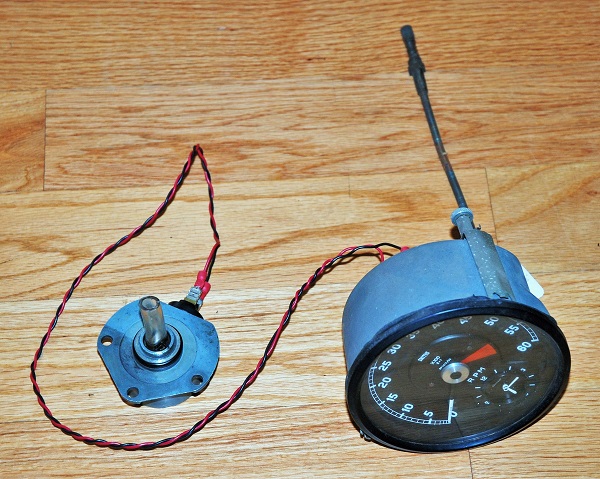

Tachometer and sending unit from a Series 1 E-type.

This is a bench-top system to test the sender and tachometer.

The sender unit is a small generator that bolts to the rear of the intake cam. The tachometer is a voltmeter that measures the voltage of the generator. This voltage rises as engine RPM rise.

|

|

|

|

|

|

Front of the crankshaft of an XK engine

The top picture shows the bare front end of the XK crank.

The lower picture shows the front end populated with the distributor/oil-pump drive gear, timing chain drive gear etc.

All these components are axially retained by the very large bolt screwed into the very front end of the crankshaft.

In the top illustration the end faces of the front main bearing shells can be seen. The juncture where the two shells can be seen adjacent to the parting line of the front main cap with the bottom face of the engine block.

|

|

|

|

|

|

|

|

|

|

Early 3.8-liter E-type bonnet

As is now well known, the early bonnet center sections had welded-in sections that had louvers stamped into them.

Later on in prouction, the louvers were stamped directly into the bonnet. See, for example, these later Series 1 louvers.

|

|

|

|

|

|

Lucas windshield washer motor

Top view of a windshield-washer motor.

Note the three contacts that operate the automatic-dispensing system of operation of these washers.

|

|

|

|

|

|

|

|

|

|

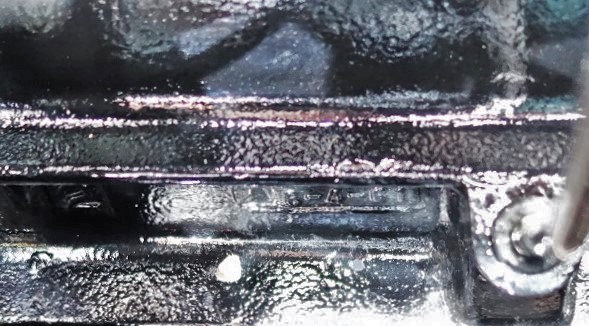

View of the lower left of an early 3.8-liter XK engine block

The casting date marking of "6-4-61" here indicates the block was poured on April 6, 1961.

The black paint on this block is much shinier than was the original paint, as is seen from all the reflections.

|

|

|

|

|

|

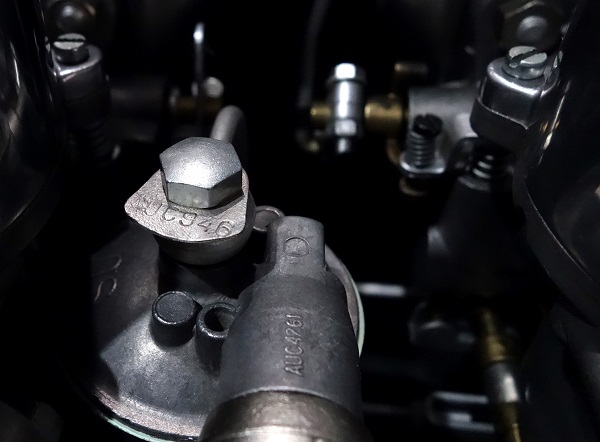

View of the top of an SU carburetor float chamber

This close-up view shows the top of the SU HD-8 carburetor float.

The AUC946 tag shows on top of the chamber overflow pipe junction.

|

|

|

|

|

|

|

|

|

|

Reservoir caps with electrical contacts

The contacts on the two hydraulic fluid reservoirs sense when the fluid level falls below a given point.

Floats inside the reservoirs position the central rods. The rods trigger switches when they fall too low.

|

|

|

|

|

|

View of the top of an SU carburetor float chamber

This close-up view shows the top of the SU HD-8 carburetor float.

The AUC946 tag shows on top of the chamber overflow pipe junction.

|

|

|

|

|

|

|

|

|

|

Reservoir caps with electrical contacts

The contacts on the two hydraulic fluid reservoirs sense when the fluid level falls below a given point.

Floats inside the reservoirs position the central rods. The rods trigger switches when they fall too low.

|

|

|

|

|

.jpg)